Posts: 985

Threads: 0

Joined: Mar 2005

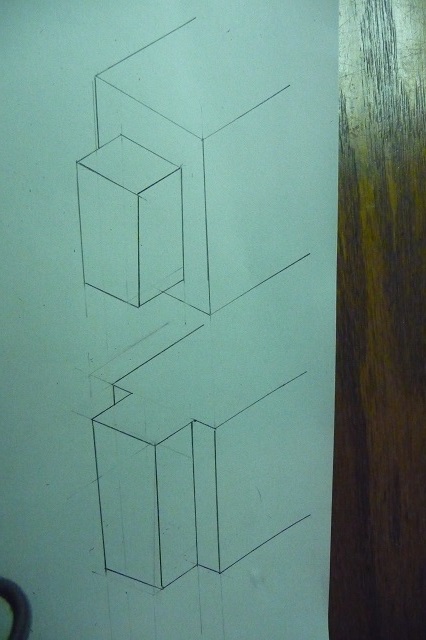

I'm a fairly competent woodworker but have never done any mortises. That all changed when I bought a mortising machine at an auction. My first project is a cherry mission style chair for the back porch. I have a very basic question concerning the sketch below:

The plans call for a blind tenon as shown on the top sketch. My question is why wouldn't the bottom sketch be better? Wouldn't it put more meat in the joint, more glue surface, and be easier to cut?

I had a good day. I used every tool I own!

Posts: 1,150

Threads: 0

Joined: Nov 2006

Location: Texas - Gods Country

It is stronger when the joint is enclosed on all 4 sides. If you take the tenon all the way to the top of the other part, it isn't as strong.

Posts: 3,545

Threads: 1

Joined: May 2004

Location: Wisconsin

Shoulders can cover imperfections: it's harder to make the joint look good without them. Shoulders lock the joint so it can't move as you try to bend it, as slight wiggles can become fully loose joints over time. Your bottom joint would have shoulders to resist motion either way, but as Strokes77 points out, the joint strength can be compromised anyway. That's because you need to consider both the tenon and the mortise. A mortise going all the way to the top of a leg loses the lock at the top, and the mortise could widen and hold less well.

Posts: 1,150

Threads: 0

Joined: Nov 2006

Location: Texas - Gods Country

And, I forgot, more than anything... the extra shoulder allows you to cover up your bruising or other mishaps around the mortise hole...

Posts: 798

Threads: 0

Joined: Jul 2009

(11-23-2018, 11:56 PM)Strokes77 Wrote: And, I forgot, more than anything... the extra shoulder allows you to cover up your bruising or other mishaps around the mortise hole...

Aw, c'mon - nobody has those problems - except me - right????

Jim

Demonstrating every day that enthusiasm cannot overcome a lack of talent!

Posts: 12,889

Threads: 0

Joined: Jan 2010

Location: Lewiston, NY

I agree with everything said above, but tests show that bridle joints are stronger than traditional M&T joints. This does not mean that M&T joints might not be the best choice for a particular application, only that they aren't necessarily the strongest option.

John

Posts: 1,407

Threads: 2

Joined: Jun 2003

11-24-2018, 10:03 AM

(This post was last modified: 11-24-2018, 10:25 AM by rwe2156.)

(11-24-2018, 10:01 AM)jteneyck Wrote: I agree with everything said above, but tests show that bridle joints are stronger than traditional M&T joints. This does not mean that M&T joints might not be the best choice for a particular application, only that they aren't necessarily the strongest option.

John

I don't see how not having wood on one side can be stronger. That's the purpose of a haunched tenon.

Regardless, pinning adds tremendous strength. A necessity on chairs.

Posts: 985

Threads: 0

Joined: Mar 2005

Thanks guys. I'm beginning to see the light, but before I lay this to rest, does it change anyone's opinion that this joint is in the middle of a leg, not at the top?

Papa Jim

I had a good day. I used every tool I own!

Posts: 2,772

Threads: 0

Joined: Oct 2012

Location: W. of Rainier, E. of Orcas

11-24-2018, 12:16 PM

(This post was last modified: 11-24-2018, 12:20 PM by hbmcc.)

(11-24-2018, 11:34 AM)Papa Jim Wrote: Thanks guys. I'm beginning to see the light, but before I lay this to rest, does it change anyone's opinion that this joint is in the middle of a leg, not at the top?

Papa Jim

Nope. However, your shoulders don't need to be so large.

Posts: 12,889

Threads: 0

Joined: Jan 2010

Location: Lewiston, NY

(11-24-2018, 10:03 AM)rwe2156 Wrote: I don't see how not having wood on one side can be stronger. That's the purpose of a haunched tenon.

Regardless, pinning adds tremendous strength. A necessity on chairs.

A bridle joint has much higher surface area than a M&T. Also, the shoulders above each check of the tenon run full length and provide the same racking resistance as the shoulders on the ends of the tenon of a traditional M&T. A haunched tenon is different than what the OP asked about, but it's purpose is mostly to prevent twist so the joint comes together flush.

Not to be a contrarian, but pinning a joint does not increase it's strength. Strength testing shows pinned joints have lower failure strength than identical joints w/o pins. Pins take away surface area; that's why. Pins do keep a failed glue joint together; that's their real benefit on something like a chair. They keep the joint together so you don't end up on the floor even though the chair may feel pretty wobbly after the glue has failed. Pins also are great for unglued joints, as many early through M&T door joints were made, and still are by some and they are plenty strong.

John