Posts: 4,011

Threads: 0

Joined: Nov 2010

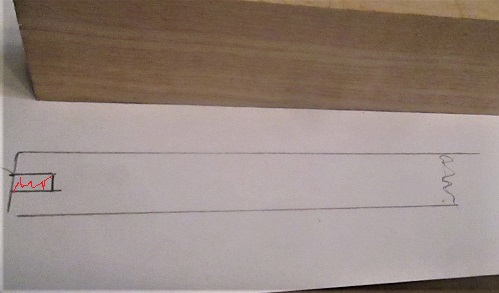

From the first really sound sleep I've had in weeks? The Single Brain Cell Sketch Up seems to have found a "different" way to join mitered corners...that leaves a bead showing....Says to start with the 4 sides of a box....maybe 3/4" x 4" x whatever long...( 6" & 12"?) and cut a groove into the ends....

Stanley 45 has trouble doing this sort of groove, might be a 2-pass on the tablesaw....then the miters get cut...

Remember, this is just on the ends of the boards......I suppose I could carry the outside beveled edges along the top edge, then make it a rebate to house the lid?

Anyway, corners will meet up like this..

Hmmm, not much to glue to? But wait, there's more...

It says to cut a bead along the edge grain of some scrap 1 x4s....then make enough cuts to "free" a spline....spline fits into those end grain grooves, leaving just that bead exposed....

Hmmm....should be interesting enough to do...will depend on when I can be allowed back into the shop, and for how long at a time....

Need to stash the Paper Plans somewhere so Boris & Natasha can't steal them....

Wonder what sort of hinges I can use.....

Show me a picture, I'll build a project from that

Posts: 4,011

Threads: 0

Joined: Nov 2010

Roh Kay..Raggy....Knee Doctor visit this morning...No tear, no surgery...however...I have a "Baker's Cyst" behind the knee. There is an option of either a shot, or just needle to drain it.....and I hate LONG, Pointy needles. Continue Rehab for now...

Decided to pay a visit TO the shop....been a few weeks, hasn't it....

Any flat surface? Floor wasn't a whole lot better..

Need a Dust-Shovel? Evicting a LOT of spiders, too...Top of the bench was slightly better..

Not much....will get to that later...first, I'll need that tablesaw cleared off..

That's better....have a 1 x 6 x 6' Ash plank to cut up a bit....I suppose I had better check for square, too..

Mitre Gauge was a couple degrees out...now fixed.

There was a load of clothes IN the dryer....brought them up upstairs..one step at a time...

Spent about 1/2 an hour total in the shop...even used the air hose to help out...knee is currently "on ice"...was a long and busy day for it...

Will see how tomorrow goes, after Rehab on that knee...

Show me a picture, I'll build a project from that

Posts: 428

Threads: 0

Joined: Apr 2006

(10-12-2021, 06:29 AM)bandit571 Wrote: ....It says to cut a bead along the edge grain of some scrap 1 x4s....then make enough cuts to "free" a spline....spline fits into those end grain grooves, leaving just that bead exposed....

Interesting idea although in my mind, seems like no matter how careful you are with grain orientation on the spline it would be prone to break if the joint were put under any stress. With a small box, perhaps not a concern.

Posts: 3,017

Threads: 1

Joined: Aug 2009

I can't quite figure out what this does for you that just gluing a bead into the corner there would do. As far as strength, splines in the miter would be better and faster.

Posts: 4,011

Threads: 0

Joined: Nov 2010

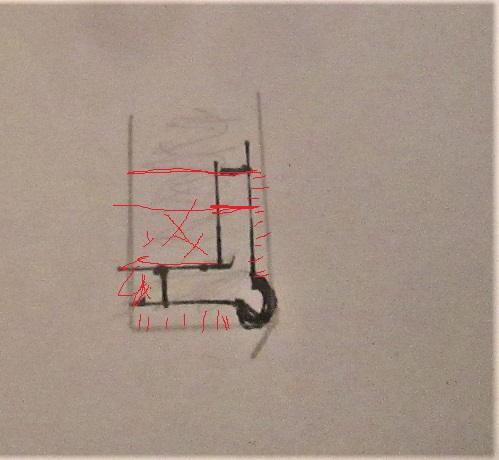

Crossing the "T" now...

Then more bevels....

Details?

Also, am trying to get the grain to wrap around...all four sides...

Working with 3/4 x 4" x either 6" or 12" long Ash.

Waiting to see how the knee feels tomorrow, before I get the Stanley 45 up and running... so far, just using the tablesaw. Even for the bevels...

First try wanted to rock a bit...added more parts to the jig..

Because the bevels AND grooves were done to the end grain.....had to use a jig,,,Not sure IF the grooves are deep enough,,,yet, we'll see.

One reason to try this sort of joint....make the "splines" out of a different colour wood...would have nice nice to have some Black Walnut in the shop....

Instead, I have Ash..

Will see how things go....along with how well the knee holds up.....1-1/2 hours today was right at it's limit....Baker's Cyst in the right knee..

Show me a picture, I'll build a project from that

Posts: 4,011

Threads: 0

Joined: Nov 2010

Knee is on ice right now...went back to the shop, tonight.....dug out the Stanley 45, and set it up with a #23 Bead cutter...and gave it a test drive....both to check it's settings,and to see how the knee responded, as it does the pushing....will see how things feel tomorrow, was a busy day for the knee...

have 3 Sargent planes I need to get shipped out...wanted to make sure they are ready.

2 are VBMs...and a small block plane...

Show me a picture, I'll build a project from that

Posts: 4,011

Threads: 0

Joined: Nov 2010

Joint an edge first....

Then half of a bead...

Rotate to form the other half of the bead..

Then remove all the waste until...

It is ready to test fit....and be cut for length....save one small section to act as a "Pattern"...

Laid out the 4 sides, according to the grain patterns..inside of the box view...

may see about using a better wood for the splines...grain wise, as Ash wants to tear out a bit around the bead...

Show me a picture, I'll build a project from that

Posts: 4,011

Threads: 0

Joined: Nov 2010

Needed grooves to house the plywood panel for the "floor" of the box......reset the Stanley 45

Needed a jig to hold things still long enough to get Groovy.....cutter is marked with a simple "T" (1/4" Tongue?)

Had to make sure that the groove went into the BOTTOM edge of each piece....TOP will get a rebate, later..

Between making splines #3 and #4..and all of that shoving the Stanley 45 around...knee had decided it had had quite enough, for the day...

Thin boards WERE going to be the floor boards.....until I found some 1/4" thick plywood...

Next time in the shop? Rebates need to be milled, BEFORE I do a glue up.....and then maybe a solid wood, Raised Panel for the lid?

Stay tuned..

Show me a picture, I'll build a project from that

Posts: 4,011

Threads: 0

Joined: Nov 2010

10-18-2021, 06:25 PM

(This post was last modified: 10-18-2021, 06:26 PM by bandit571.)

2 set-ups on the tablesaw...2 passes to do the rebate for the lid to sit in...done... one dry fit to check the size of the 1/4" plywood panel....needed a slight trim...was getting mean...parts acting like there was a giant magnet in the floor, that attracted the heck out of wood....getting parts to stand up, was like giving a Drunk Driver a field test...

So...war was declared....hammer in hand, we be doing a glue up...NOW!

Always one part that wants to fight...in this case, one of the splines....which waited until the last hit to break a chunk off...onto the floor...hmmm..

Cleaned it up more glue added...HAMMERED it into place

Too many parts, too many clamps...too few hands...worse than trying to herd cats...was able to finally stand this mess up, to check on the insides..

Intend to let this sit a day.....that "Monday Thing"...

Next up? Clean, plane, and sand...and fit a raised panel lid to the box....

Stay tuned..

.( NEEDED a couple Guinness Draught STOUTS when I got back upstairs..)

Show me a picture, I'll build a project from that

Posts: 4,011

Threads: 0

Joined: Nov 2010

And..now out of the clamps....lid has been shaped....and everything cleaned up, and sanded to 220 grit...for now...

Have a Dremel Contour Sander ( Yard Sale) that has an insert that matched the shape of the spline's bead...

Strip of 220 grit wrapped around the insert....medium speed....done..

Trying to decide which will be the "Front" of the box....and then see about some hardware. Might see about a small tray for the inside?

Stay tuned...

Show me a picture, I'll build a project from that

|