Posts: 1,057

Threads: 0

Joined: Jun 2005

Location: Peoria, IL

04-20-2020, 05:54 PM

(This post was last modified: 04-20-2020, 06:03 PM by gov.cheese.)

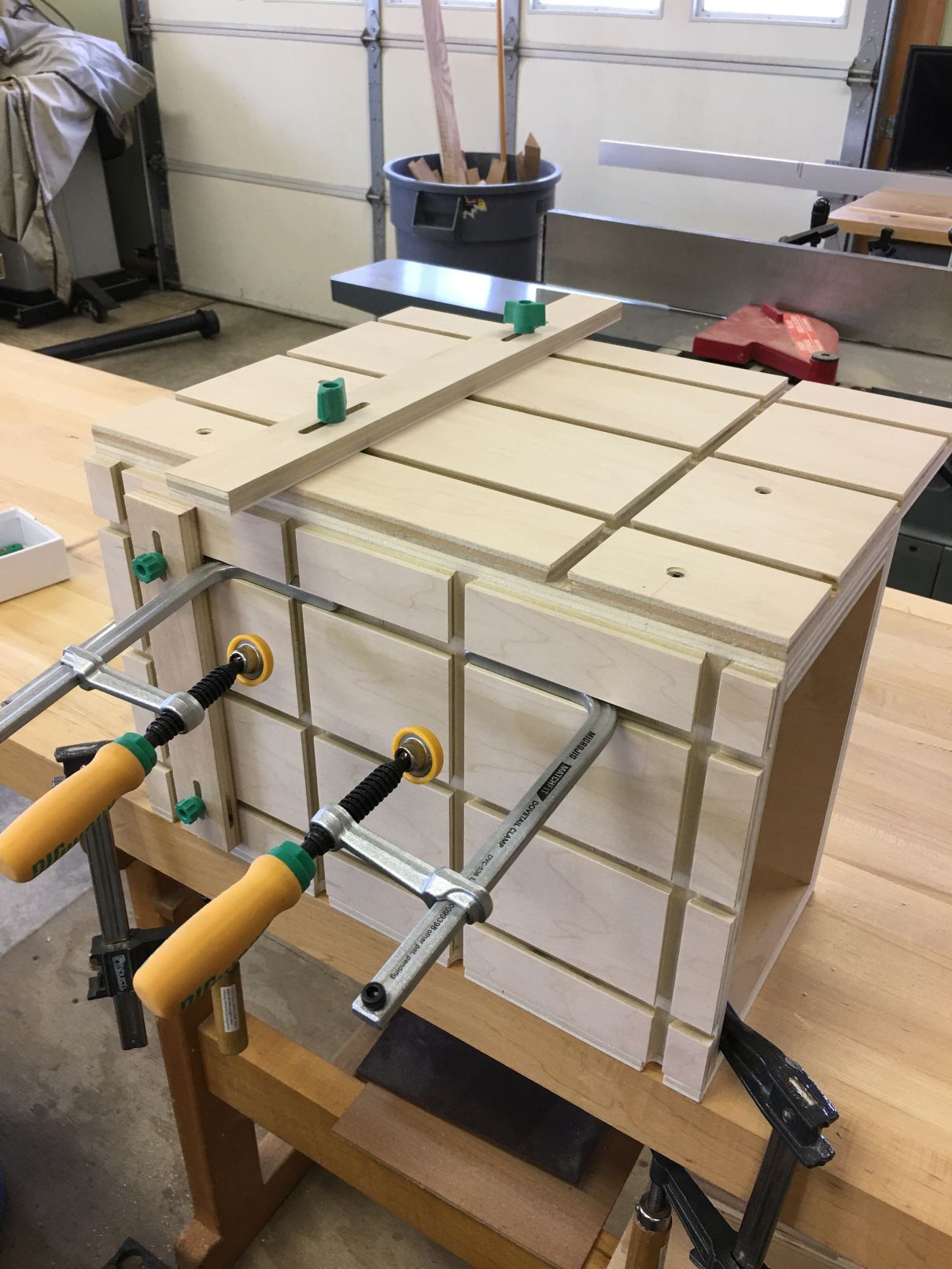

Mike Pekovich had an article in the lastest FWW where he built what he called an 'all-in-one workstation for dovetails'. I took his idea and swapped out the toggle clamps for the Micro Jig system. The box is dadoed, glued and the top is screwed on so it can be replaced. I made this today so it goes together pretty quick.

Posts: 2,341

Threads: 0

Joined: Jan 2008

Location: Irving, Tx

I saw the article in FWW, haven't read it yet. I did four drawers three weeks ago. I can see how your station would have made things move a little faster.

"I tried being reasonable..........I didn't like it." Clint Eastwood

Posts: 833

Threads: 0

Joined: Aug 2014

It looks nice! I'm sure there are critiques of one sort or another, but when I saw it I felt like it could serve OK for me.

Chris

Posts: 174

Threads: 0

Joined: May 2018

fantastic idea, thanks for sharing.

Posts: 797

Threads: 0

Joined: Apr 2007

(04-20-2020, 05:54 PM)gov.cheese Wrote: Mike Pekovich had an article in the lastest FWW where he built what he called an 'all-in-one workstation for dovetails'. I took his idea and swapped out the toggle clamps for the Micro Jig system. The box is dadoed, glued and the top is screwed on so it can be replaced. I made this today so it goes together pretty quick.

This looks quite handy. I bet you use it for more than just dovetails.

Ron

Posts: 3,738

Threads: 0

Joined: Nov 2010

Hmmmm..afraid my Dovetail Station is me, sitting down on the Shop Stool, sawing, and chopping away....either with the part in the end vise, or clamped flat on either a flat board, with both clamped down to the top of the bench....or just the part, before it is flipped over, and onto that flat chopping board. Same with the Finger/Box Joints I do by hand. In fact, about any joinery work with a saw, and/or a chisel(s) will involve me sitting down on the job....I'm closer to the work, and can adjust up or down as needed...by just moving the part....usually right after lay out, and right before the saw comes along.

Show me a picture, I'll build a project from that

Posts: 6,938

Threads: 0

Joined: Aug 2004

Location: Perth, Australia

I looked at the fixture made by MP. The clamps he uses are better than the Micro Jig clamps in that they are lower profile, and are less likely to get in the way when sawing half-blinds. I have used the Micro Jig clamps fir a number of task and they are good clamps. Just project too much for this task. The issue I have with the toggle clamps is that it does not appear obvious how MP is able to adjust for width.

Regards from Perth

Derek

Posts: 2,376

Threads: 0

Joined: Dec 2011

04-22-2020, 11:17 AM

(This post was last modified: 04-22-2020, 11:18 AM by Handplanesandmore.)

(04-21-2020, 06:07 PM)bandit571 Wrote: Hmmmm..afraid my Dovetail Station is me.

I agree this DW is an overkill for dovetail work. It is no more than a complicated version of Barron's dovetail jig, and in fact for dovetails, it isn't as good as Barron's jig.

BUT, it is useful for other hand work or router tasks as well, and so it would be like a bench on bench kind of fixture. Worth building one if the intention is not to use it solely for dovetail work.

Simon

Posts: 12,261

Threads: 0

Joined: Mar 2006

I'm missing something here! I thought the Barron dovetail jig was a magnetic saw guide?

Posts: 2,376

Threads: 0

Joined: Dec 2011

04-22-2020, 12:34 PM

(This post was last modified: 04-22-2020, 12:35 PM by Handplanesandmore.)

(04-22-2020, 12:20 PM)Tony Z Wrote: I'm missing something here! I thought the Barron dovetail jig was a magnetic saw guide?

His dovetail alignment jig. It has fixed fences.....dead on every time, unlike the loose fences in Mike's station that need to be aligned every time.

Simon