10-13-2018, 03:15 PM

A while back, I posted here asking about the possibility of replacing the broken trunnions on a 14" Steel City bandsaw I had been given. Long story short, there were a few generic trunnions available online, but I didn't really want to take the chance of them not fitting. Plus, I had an inkling of how I could fabricate my own.

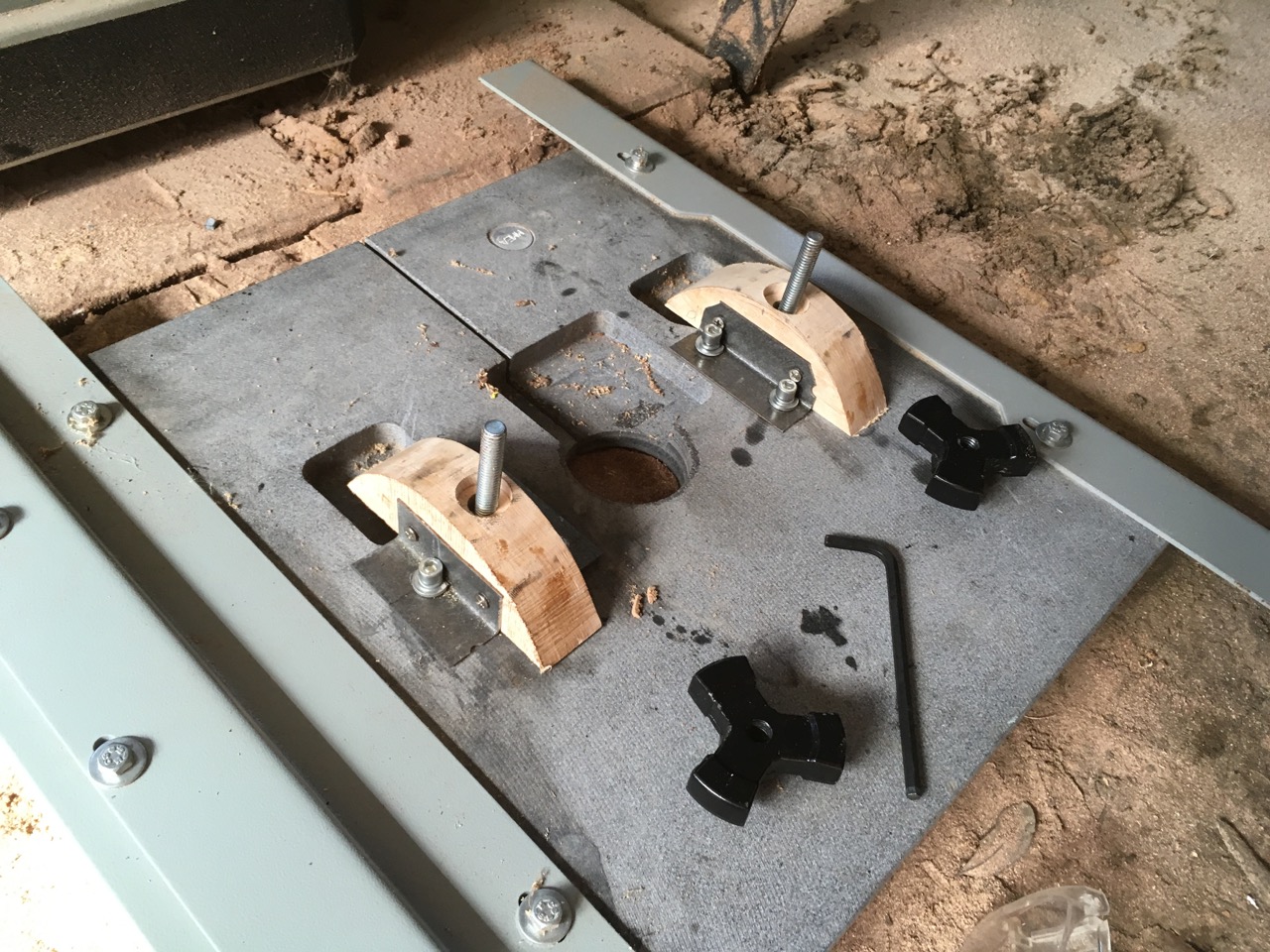

One simplification is that I did not need the bandsaw table to be able to tilt. So I just needed the table to sit solidly on the base. I decided to use some hard maple blocks, sawed to the right radius, and attach them to the table with angle iron. Here's the process:

Probably the hardest part was making sure the radius was a match. I started by trying to trace one of the broken trunnions, but I couldn't get the block close enough to the radius to get an accurate trace. So I just used the mating surface, like this. I went ahead and traced out the whole radius, but in reality, only about a half of the radius is in contact with the base.

I sawed out the radius on my old bandsaw (which I thankfully still have). If I hadn't had that, I would have resorted to a coping saw.

I clamped them together and smoothed out the saw marks with a file. It doesn't need to be especially smooth or pretty, but the trunnions do need to be exactly the same size.

After drilling through them and counter-boring the tops for the bolt head, they fit nicely onto the base! The bolt hole is drilled oversize, which provides just a bit of wiggle-room in fitting everything together. I probably should have also drilled the counter-bore a little bit oversize, too, but this worked.

I used the old, broken trunnion to figure out how long each piece of angle-iron should be. I attached the angle-iron to the wooden blocks with screws, and then I drilled out the oversize holes in the angle iron for the bolts that will attach the new trunnions to the underside of the table.

Finally, I bolted the new trunnions onto the table. I ended up putting in the bolts loosely, setting the whole thing on the base to get the trunnions positioned correctly (because of the oversize mounting holes, there's a bit of wiggle room), and then snugging down the bolts.

Now, what you've read is the streamlined version of the process. I had to make a number of little adjustments here and there, and there were some missteps along the way. For example, when I went to bolt the trunnions to the bottom of the table, I found that they were just a little bit too wide, and while the mounting bolts fit okay, their washers didn't. I think I forgot to factor in the thickness of the angle iron on both sides when cutting the blocks to thickness! So I just use a grinder to take 1/8" off the edge of each washer. Another funny thing: I accidentally counter-bored the wrong side of the trunnions at first (visible in the picture above). But it doesn't affect how they mate to the base, so I just left it there.

But now the table sits nice and secure. Because the bolt holes are oversized, it is possible to adjust the table by a few degrees in either direction, which is just as well because I needed to use the set-screw to get everything leveled.

So now the saw us usable again.

One simplification is that I did not need the bandsaw table to be able to tilt. So I just needed the table to sit solidly on the base. I decided to use some hard maple blocks, sawed to the right radius, and attach them to the table with angle iron. Here's the process:

Probably the hardest part was making sure the radius was a match. I started by trying to trace one of the broken trunnions, but I couldn't get the block close enough to the radius to get an accurate trace. So I just used the mating surface, like this. I went ahead and traced out the whole radius, but in reality, only about a half of the radius is in contact with the base.

I sawed out the radius on my old bandsaw (which I thankfully still have). If I hadn't had that, I would have resorted to a coping saw.

I clamped them together and smoothed out the saw marks with a file. It doesn't need to be especially smooth or pretty, but the trunnions do need to be exactly the same size.

After drilling through them and counter-boring the tops for the bolt head, they fit nicely onto the base! The bolt hole is drilled oversize, which provides just a bit of wiggle-room in fitting everything together. I probably should have also drilled the counter-bore a little bit oversize, too, but this worked.

I used the old, broken trunnion to figure out how long each piece of angle-iron should be. I attached the angle-iron to the wooden blocks with screws, and then I drilled out the oversize holes in the angle iron for the bolts that will attach the new trunnions to the underside of the table.

Finally, I bolted the new trunnions onto the table. I ended up putting in the bolts loosely, setting the whole thing on the base to get the trunnions positioned correctly (because of the oversize mounting holes, there's a bit of wiggle room), and then snugging down the bolts.

Now, what you've read is the streamlined version of the process. I had to make a number of little adjustments here and there, and there were some missteps along the way. For example, when I went to bolt the trunnions to the bottom of the table, I found that they were just a little bit too wide, and while the mounting bolts fit okay, their washers didn't. I think I forgot to factor in the thickness of the angle iron on both sides when cutting the blocks to thickness! So I just use a grinder to take 1/8" off the edge of each washer. Another funny thing: I accidentally counter-bored the wrong side of the trunnions at first (visible in the picture above). But it doesn't affect how they mate to the base, so I just left it there.

But now the table sits nice and secure. Because the bolt holes are oversized, it is possible to adjust the table by a few degrees in either direction, which is just as well because I needed to use the set-screw to get everything leveled.

So now the saw us usable again.

Steve S.

------------------------------------------------------

Tradition cannot be inherited, and if you want it you must obtain it by great labour.

- T. S. Eliot

Tutorials and Build-Alongs at The Literary Workshop

------------------------------------------------------

Tradition cannot be inherited, and if you want it you must obtain it by great labour.

- T. S. Eliot

Tutorials and Build-Alongs at The Literary Workshop

Looks like a great solution

Looks like a great solution