▼

Posts: 3,719

Threads: 0

Joined: Nov 2010

06-10-2021, 10:09 AM

(This post was last modified: 06-10-2021, 10:12 AM by bandit571.)

Wasn't sure IF anyone wanted to follow along....involves a bit of saw work..

To transform 4/4 scraps into 3/8" stock....

More saw work..

To make hand chopped box/finger joints....

Not to mention a lot of hand plane work..

Both the flatten the sawn faces of the boards, but...

Jointing a few edges, in case I want a glued up panel for a lid..

Have 3 out of 4 corners milled, trying to get the grain to wrap around the box....

So...IF anyone wants, I could start a build along thread.....Has the usual suspects...

Although, one is under arrest...

Knife to do "Knife Wall" work.....assaulted a thumb on the way by..

Never felt a thing. So, anyone interested?

Show me a picture, I'll build a project from that

▼

Posts: 3,719

Threads: 0

Joined: Nov 2010

06-10-2021, 01:39 PM

(This post was last modified: 06-10-2021, 01:50 PM by bandit571.)

Ok, to get started...had a stack of scraps from the Table project..

[attachment=35762]

So. to reduce the thickness and double the board count, set the saw blade as high as it could go. Set the rip fence to the center of the board's width..

[attachment=35763]

Hmm, doesn't reach quite far enough, does it? We have ways..

[attachment=35764]

Happen to have a D8 Rip saw handy ( just been sharpened, BTW) so...the shorter 3 boards used this set up..

[attachment=35765]

Have to be careful, as when I reach the bottom of the cut...

[attachment=35766]

The halves tend to pop apart....soon had 6 blanks..

[attachment=35767]

From 3 planks. The longer 3 planks, I wanted a bit more elbow room...to get that 28" stroke..

[attachment=35768]

Used a c clamp to keep things from tipping over. Got down to about 1-2" from that clamp, flipped the board over, and came down from the other end..

[attachment=35769]

Soon had 6 of the longer wider boards....all were just a hair over 3/8" thick....some will need a bit more work than others..

[attachment=35770]

Still had a stack of narrows....

[attachment=35771]

I figure I can rip these as needed....as for the resawn stuff...will need a plane..

That will be next time......stay tuned

Show me a picture, I'll build a project from that

Posts: 2,766

Threads: 0

Joined: Oct 2012

Location: W. of Rainier, E. of Orcas

Man!! How do you manage hand sawing?

I had ambitions to do the same hand work but my new shoulder is giving me fits. A whole bunch weaker and a real chore to get over the pain hump when planing and sawing. I'm redoing the front porch this summer.

I guess you just barrel through it....

Look forward to watching your progress, Steve.

Heirlooms are self-important fiction so build what you like. Someone may find it useful.

Posts: 3,719

Threads: 0

Joined: Nov 2010

That D8 had just been sharpened up...needed to be used. Nice long full strokes, about like a pit sawyer would use....no need to get into any rush....just let the saw do the work. Each stroke cuts quite a bit down through. By using the tablesaw to cut those kerfs, I even saved a bit of work....much easier to start the saw.

Tablesaw also was used to 4-square the longer blanks,,going from...

[attachment=35799]

A mess like this to..

[attachment=35800]

All squared away. Then the planes can take over...a "Before & After" look...

[attachment=35801]

So that when both halves are planed smooth and flat...

[attachment=35802]

All that is needed is some jointer work..

[attachment=35804]

So I can have a decent book match..

[attachment=35805]

This one is a bit too "busy"....will use something more like this for a lid...

[attachment=35806]

Some needed a little bit of beltsanding...most took a Millers Falls No. 15....a couple spots I used the Millers Falls No. 9, Jointing was with the WR No. 62...

[attachment=35809]

This being the No. 15 in use.....slightly larger than a normal No. 5 Jack plane...

[attachment=35810]

Like this Millers Falls No. 14. Plan right now, is to take the largest 2 from this stack, and the narrow two from the 12" long stack, match them up into 4 sides of a box..

[attachment=35811]

May involve a few rip cuts, and a few crosscuts until they all match in width, width squared ends..

Stay tuned..

Show me a picture, I'll build a project from that

Posts: 3,719

Threads: 0

Joined: Nov 2010

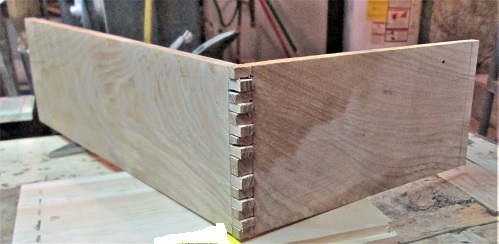

4 sides...2 at 8" long, 2 at 12" long.....3/8" thick (more or less) by 3-5/8" tall...

[attachment=35821]

Will do as a start...need to round up all the usual suspects...for making finger/box joints by hand tool..

[attachment=35822]

Hmmm...missing one...must be upstairs...

[attachment=35823]

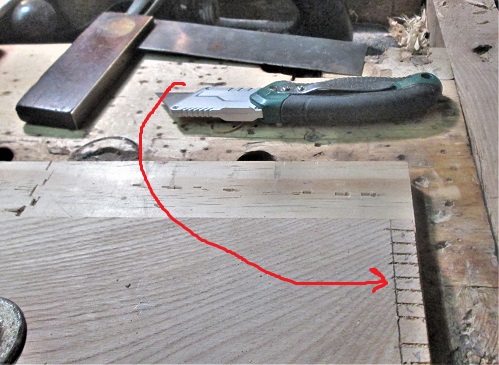

To make a knife wall, one needs a knife. The chisel was first, needed to set the spacings of the fingers..

[attachment=35824]

usually right on the end grain...sometimes two boards go through the layout...

[attachment=35825]

Then that small square can carry the marking around...

[attachment=35826]

With the marking gauge providing a "stop line" to mark the saw lines to. usually works best IF just one part is sawn at a time..

[attachment=35827]

Saw does not like a lot of vibration either....I keep the board low in the vise....works, since I am usually sitting down on the shop stool to do this sort of work...about 8 full strokes to complete each cut....then set up a chopping board ( to protect the top of my bench, right) and cut the knife wall..

[attachment=35828]

Grab that chisel again....I chop down about 1/2 way....leave a little porch out on the ends...then flip the board over..

[attachment=35829]

And complete the chopping...all nice and clean...I start from the outside (show) side first, then finish the chops from the "inside"....need to mark which is which, too

[attachment=35830]

Tends to be very useful information....panels all tend to look alike. I work from the shorter "ends" first. Once those fingers are chopped, I use them to lay out the matching fingers on the "side" panels....and saw and chop those.

Stay tuned..

Show me a picture, I'll build a project from that

Posts: 3,719

Threads: 0

Joined: Nov 2010

Ok, sides were getting sawn and chopped to match...Had one end that needed a bit extra work....seems that fancy grain...

[attachment=35831]

Caused that middle finger to break off....so, the side had to match that..

[attachment=35832]

Got into a issue...as to which corner was next...and still allow the grain to flow around the box...instead of #3...#4 was done...

[attachment=35833]

Dry fit?

[attachment=35834]

Even sits square. Next shoptime, #3 corner was sawn..

[attachment=35835]

Chopped..

[attachment=35836]

And dry fitted....

[attachment=35837]

So...next time will be a glue up adventure....

stay tuned..

Show me a picture, I'll build a project from that

Posts: 3,719

Threads: 0

Joined: Nov 2010

06-14-2021, 07:59 AM

(This post was last modified: 06-14-2021, 08:00 AM by bandit571.)

Glue up time!

First a dry run with the clamps...to preset them so I don't have to stand there and fumble with them AND wet glue..

[attachment=35849]

8....just 8?...for now...Bought a bag at Harbor Freight the other day...

[attachment=35850]

And got out a couple...

[attachment=35851]

Lots of fingers to spread the glue around...one brush to spread with, the other to clean off any squeeze outs...OK, let the fun begin..

[attachment=35852]

Put a couple LONG (18") clamps on first, stick the ends down into the vise....then let the flash mob continue...pine stays to prevent bowing in on the ends

[attachment=35853]

Turned out, I also needed a couple to prevent the sides from also bowing in...c clamps needed to pull the stays into place,,,with a few well aimed hammer shots..

Added 2 more in the middle of the ends, had an issue with that spot not closing up

Clamp Count? 12....will wait and see...how well it turned out...Sunday night.

Stay tuned

Show me a picture, I'll build a project from that

Posts: 3,719

Threads: 0

Joined: Nov 2010

Clamps can come back off, now.....slowly..

[attachment=35870]

First 8 removed, leaves...

[attachment=35871]

Four 18" long clamps....then a bit of clean up...

[attachment=35872]

Between a beltsander to wear down the high fingertips, and a smooth plane to level the rest of each side. I left a couple spacers in, due to a side that kept trying to bow in..

[attachment=35873]

Set this aside, for now....worked on the lid a bit..jointed the edges for the glue joint...

[attachment=35874]

See how it goes together....

[attachment=35875]

Might as well glue it up?

[attachment=35876]

and let this sit a day....

Bottom panel is a 1/4" plywood panel, that will get glued down to "Slips". First, I need to rip a bit of stock once..

[attachment=35877]

Took 2 passes, otherwise the board slips down into the saw...or worst. and ruins my store bought pushstick.....reset the fence a bit..

[attachment=35878]

This is the shop-built pushstick....been nicked a few times. Long enough to guide the entire piece through. I can then go back, and plane these 4 blanks smooth.

[attachment=35879]

Slips will then get glued in place, with a mitered corner....need a Mitersaw for that. waiting on glue to dry...again...

Stay tuned

Show me a picture, I'll build a project from that

Posts: 3,719

Threads: 0

Joined: Nov 2010

06-16-2021, 01:56 PM

(This post was last modified: 06-16-2021, 01:57 PM by bandit571.)

Slips have been cut to length..

[attachment=35894]

Cordless Mitersaw? Each was then glued and clamped into it's place..

[attachment=35895]

With however many clamps it took...most of the joints were fairly tight...

[attachment=35896]

There always seems to be That One, though...

[attachment=35897]

Let this mess sit a day....

[attachment=35898]

Next day..cut a 1/4" thick plywood panel for the bottom of the box. Brush a bead of glue along the slips...use a set of cauls to press the panel down into the glue...Then work on the blank for the lid...bandsaw to round 2 corners..

[attachment=35899]

Millers Falls No.9 to smooth both faces..

[attachment=35900]

Spokeshave is to remove the burn marks left by the bandsaw. It was also to help round over the edges..

[attachment=35901].

To help? Well, there is a Stanley No. 9-1/2 also at work, here. It also shot the end grain straight...and ..

[attachment=35902]

Worked with the spokeshave...

[attachment=35903]

had to make a run to the store, yesterday....needed hinges, a latch....and a Rueben Sammich.....

Maybe later today, I can see about removing the clamps..again, and work on the inside details?

Stay tuned

Show me a picture, I'll build a project from that

Posts: 3,719

Threads: 0

Joined: Nov 2010

Box is out of the clamps used the glue in the floor...top of the box needed to be leveled..

[attachment=35920]

Ends were a tad too high, and two corners were high than the other two...goal is for the lid to sit fairly flat..

[attachment=35921]

Box was rocking a bit....needed to get the slips AND the corners all leveled up..

[attachment=35922]

Same plane as before, since it was already sitting out....Millers Falls No. 9, Type 4

[attachment=35923]

Looks a wee bit better....

[attachment=35924]

May trim the lid back just a bit...seems a bit overpowering to the box....We'll see..

Hardware?

[attachment=35925]

There be a choice of hinges....

[attachment=35926]

A latch and the brass feet plates....

Sand, fill, sand...stain, hardware install.....see about a tray or two....Boring anybody?

Show me a picture, I'll build a project from that

|