06-25-2017, 10:41 PM

Much of the work I do involves fairly accurately setting my drill press fence. I've typically used spacers between the fence and the bit, but that involves keeping track of a lot of spacers or having to always make new ones.

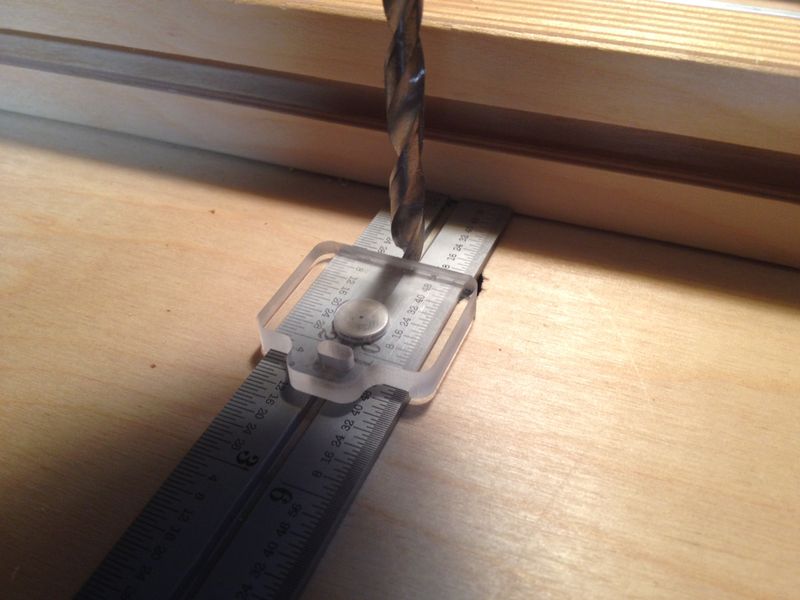

So today I made an acrylic indicator for my 1" wide Starrett rules.

The indicator has shoulders that hug the edges of the rule. The embedded magnet provides just enough pull that I can slide the indicator with finger pressure, but it stays put once I remove pressure.

To use it, I lock the quill so the bit is just a little above my rule. As I slide the rule under the bit and towards the fence, the bit "pushes back" against the indicator, sliding it along the rule.

Once the rule is pushed all the way to the fence, I can remove the rule and read the indicator. I can make small adjustments to my fence and take another reading very quickly.

In the pictures, I want the 1/4" bit centered 1" from the edge of my board. So I need the indicator to read 1-1/8" (1" + 1/2 the diameter of my bit).

Hopefully this will save me a bunch of time cutting spacers or looking-around for spacers I've already cut but later used for something else (I do that all the time).

This should also come in handy for checking depths of grooves, etc. I have a full compliment of calipers but honestly don't always want values in .001". The advantage of this sliding indicator is that I can read any scale I prefer on my rule.

I made mine on my CNC router but no reason someone couldn't make something similar from wood.

(Just because I know someone will ask, the other side of my unit with the slot and offsets in the plastic let me read the center line to the chuck using 1/8" drill rod, handy for when I'm working with metric bits or bits with funny diameters.)

So today I made an acrylic indicator for my 1" wide Starrett rules.

The indicator has shoulders that hug the edges of the rule. The embedded magnet provides just enough pull that I can slide the indicator with finger pressure, but it stays put once I remove pressure.

To use it, I lock the quill so the bit is just a little above my rule. As I slide the rule under the bit and towards the fence, the bit "pushes back" against the indicator, sliding it along the rule.

Once the rule is pushed all the way to the fence, I can remove the rule and read the indicator. I can make small adjustments to my fence and take another reading very quickly.

In the pictures, I want the 1/4" bit centered 1" from the edge of my board. So I need the indicator to read 1-1/8" (1" + 1/2 the diameter of my bit).

Hopefully this will save me a bunch of time cutting spacers or looking-around for spacers I've already cut but later used for something else (I do that all the time).

This should also come in handy for checking depths of grooves, etc. I have a full compliment of calipers but honestly don't always want values in .001". The advantage of this sliding indicator is that I can read any scale I prefer on my rule.

I made mine on my CNC router but no reason someone couldn't make something similar from wood.

(Just because I know someone will ask, the other side of my unit with the slot and offsets in the plastic let me read the center line to the chuck using 1/8" drill rod, handy for when I'm working with metric bits or bits with funny diameters.)

"Links to news stories don’t cut it." MsNomer 3/2/24