01-26-2021, 04:43 PM

First off. I am not a fan of Sargent planes. I was at an auction last fall and there was this rusty Sargent plane that I was not even going to bid on. The plane looked to be really in bad shape because I got it for $2.

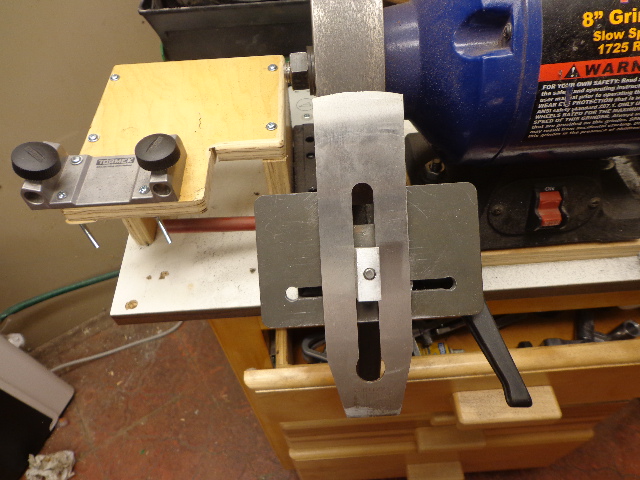

I got to thinking about Paul Sellers. He used a #4 for a scrub plane, so I took it apart, cleaned the years of grime and rust off with a wire wheel on my bench grinder and then I milled the mouth opening bigger. I am not sure

how big the opening should be. If I got it to big I am out $2.

I reground the top and bottom of the plane iron and then I ground about a 4 inch radius on the blade. There is about 3/32 arc on the blade Again I don't have a clue id it is big enough or if the radius needs to be smaller.

I need to go over to my shop and take it for a spin. Our winter storm warning just ended at noon today and since my shop is unheated it will have to wait for a better day, but I am looking forward to using it.

just a couple more pictures,

This is not restoring this is repurposing.

I hope this gives you something to think about.

Tom

I got to thinking about Paul Sellers. He used a #4 for a scrub plane, so I took it apart, cleaned the years of grime and rust off with a wire wheel on my bench grinder and then I milled the mouth opening bigger. I am not sure

how big the opening should be. If I got it to big I am out $2.

I reground the top and bottom of the plane iron and then I ground about a 4 inch radius on the blade. There is about 3/32 arc on the blade Again I don't have a clue id it is big enough or if the radius needs to be smaller.

I need to go over to my shop and take it for a spin. Our winter storm warning just ended at noon today and since my shop is unheated it will have to wait for a better day, but I am looking forward to using it.

just a couple more pictures,

This is not restoring this is repurposing.

I hope this gives you something to think about.

Tom