Posts: 527

Threads: 0

Joined: Feb 2021

Location: Stevi, Montana

(04-23-2021, 04:20 PM)Roly Wrote: I would pull it , you probably won't be able to push it around the bends. If you try to assemble the conduit as you go you will get glue on the cable also. Also it is not code to assemble the conduit with the wire inside it for what it's worth. Strongly suggest the cable lube, it is waxy and will make it way easier, 135' is a lot of drag. Apply more lube as you pull.

When bundling the conductors together stagger them to make the leading edge tapered. Also make sure they stay together by stripping the wires and twisting the ends ( still staggering) or securing together by other means. Tape the leading end so a conductor end cannot be stuck by a conduit joint. Roly

I was fortunate, mine was a straight run from the box to the shop

Pulled it thru each section, then assembled the sections of schedule 40 pvc

Posts: 22,729

Threads: 0

Joined: Feb 2005

Location: Regina Saskatchewan Canada

Go back to the vertical conduit only plan.

Blackhat

Bad experiences come from poor decisions. So do good stories.

Posts: 19,076

Threads: 0

Joined: Jul 2002

Location: Ohio

Is that legit blackhat...just using the quadplex linked in OP? Or should I use service entrance with the outer jacket? https://www.lowes.com/pd/Southwire-South...ot/4294349

Ceiling is 18', so risk of damage is extremely low. Run it on top of rafter?

I like that plan better...but don't want to do something dumb!

Posts: 2,201

Threads: 1

Joined: Oct 2003

04-24-2021, 04:13 AM

(This post was last modified: 04-24-2021, 04:57 AM by srv52761.)

Edit: So you have a service panel in your barn, and you will be adding a sub panel in a different part of your barn? If so, use SER and wire your sub panel as if you were wiring any new appliance 240 volt outlet. Just make sure not to bond the ground and neutral in your sub panel. Much of my post assumed you were running a new panel TO your barn from somewhere else.

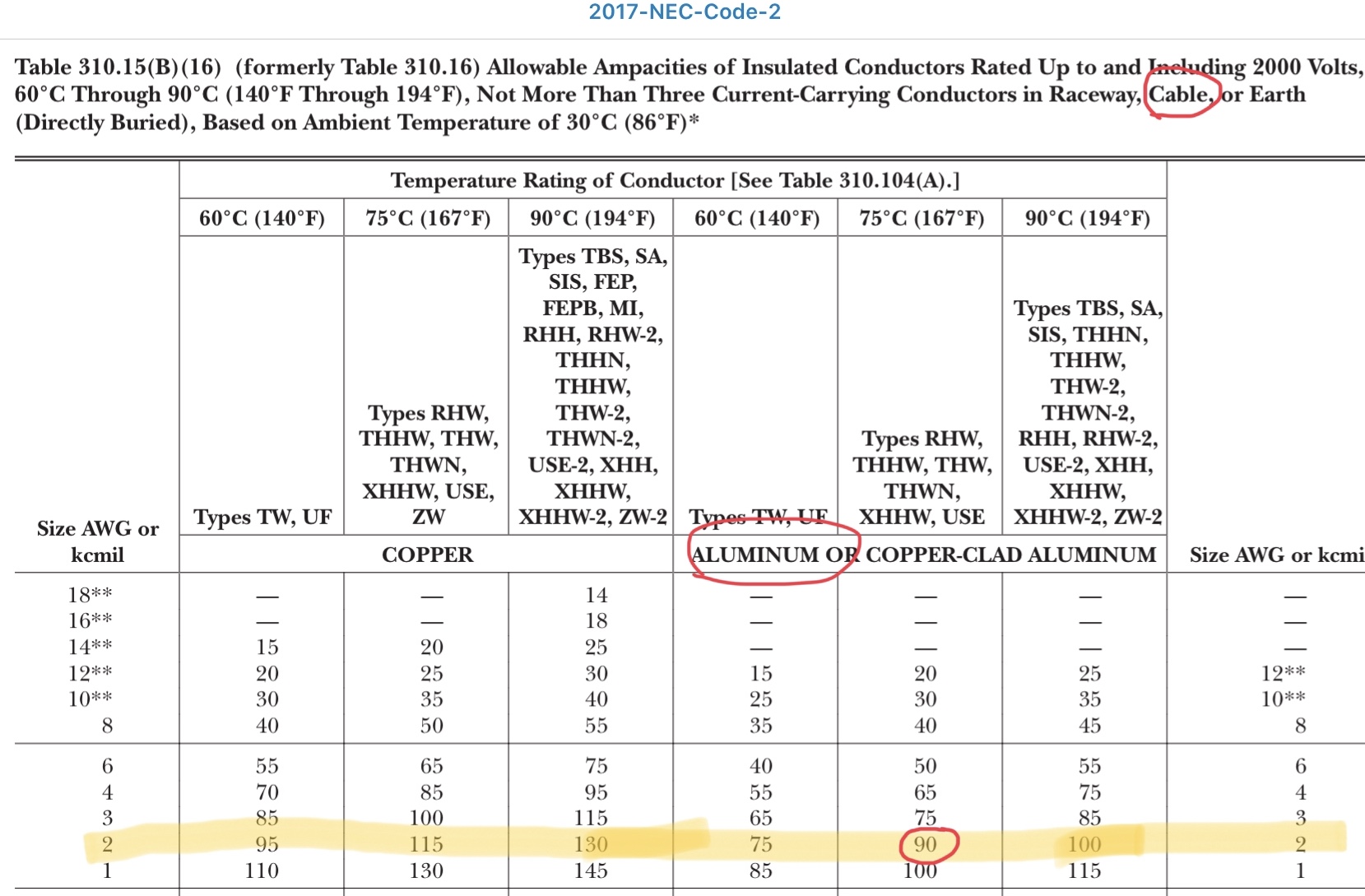

2-2-2-4 Aluminum is only rated for 90 amps. It is allowed for 100 amps under the 80% rule if it supplies all of a family residence. As a sub panel NEC says 90 amps.

URD (check to make sure it is dual rated and says RHH or RHW-2, I used MHF) can be run indoors, but needs to be in conduit.

You can transition to 2-2-2-4 SER inside. Then you could run it like Romex. Morris connectors

I ran 2-2-2-4 MHF in 1.5", and as mentioned, 1.5" LB are not pretty. You can upsize the LBs and use reducers to get back to your conduit size, done all the time.

Assemble the run before pulling, one inadvertent drop of solvent, unnoticed, can ruin your whole day. Make sure the conduit bells are facing the correct way for your pull.

Besides offsetting the first conductor of my pulling head, I load the front of the other conductors with paper towels before taping. This softens any hard edges. They make a pulling sock that does the same thing, but this only costs a nickel's worth of tape.

As mentioned, use lube generously. Soak a few rags with lube, tie them to your pull rope a few feet apart in front of your conductor head. Then have your helper continually lube the cables as they feed it in the conduit.

As mentioned, pull as one cable as twisting makes it difficult. Your cable will come with a twist. Consider untwisting if you use LBs instead of sweeps. I ran my pull as separate pulls through each LB. Separate pull rope for each section.

All the cable through the in conduit and out the LB. Big loop and attached the original rope to the next pull rope in turn, then feed through the out conduit. As the loop gets tighter in the LB as you get closer to finishing the pull through that LB, it is easier to seat them in the LB if you pull the individual conductors. Have a dry cloth to clean the lube for a good grip and a pair of neoprene palmed gloves to help pull. Relube after seating (you can also add more lube to those rags as they pass the LBs).

To that end, the person feeding the conductors is more important to the pull then the puller. They must keep lubing and working to keep the conductors from twisting as they enter the conduit. It is a very simple, but important job.

Posts: 2,201

Threads: 1

Joined: Oct 2003

04-24-2021, 04:37 AM

(This post was last modified: 04-24-2021, 04:38 AM by srv52761.)

(04-23-2021, 08:10 PM)JosephP Wrote: Is that legit blackhat...just using the quadplex linked in OP? Or should I use service entrance with the outer jacket? https://www.lowes.com/pd/Southwire-South...ot/4294349

Ceiling is 18', so risk of damage is extremely low. Run it on top of rafter?

I like that plan better...but don't want to do something dumb!

I am not sure I can picture your description; on top of rafter would be the roof decking?

SER can be run the same as nm-b (Romex).

It can be run on top of ceiling joists or collar/rafter ties (assuming that is what you meant instead of rafters). If running on top it must still be protected from damage. In our area, the inspector interprets that to be if you can stand between the rafter and the rafter tie then it needs protection.

Posts: 19,076

Threads: 0

Joined: Jul 2002

Location: Ohio

Yes...from main panel in barn to subpanel on other side of barn. Just trying to avoid needing to pull 100' of wire every time I want a new outlet of light. Not "necessary" now, but I thint it makes sense for the long-term.

On top of rafters...I meant the roof joist. This is a pole barn, so it is a 10' gap between rafters. May need to put a 2x4 between to run the wire on / provide something to attach it to? (Probably more expensive than conduit...but easier to run the wire).

The wire I linked in OP:

Allowable Ampacity 90°C (Amps) 155

Allowable Ampacity in Ducts (Amps) 115

Looks like SER has lower rating. MHF says 100 Amps. That is what the wire is rated for. Understanding local codes may say different...but no code here so as long as the wire can safely handle the load that is not an issue.

Appreciate the tips! Sounds like I should avoid conduit across the roof joists. I'll snap a pic or 2 when I am out there.

Main panel isn't even installed yet... They are doing that in 2 weeks. Meter is set on the pole and is on. 3" conduit from meter to barn is in ground and ready...so hopefully that goes quickly for them.

Posts: 18,627

Threads: 0

Joined: Jul 2006

Location: Milwaukee area

"Go back to the vertical conduit only plan."

Consider building a raceway for the vertical, as well.

Posts: 2,201

Threads: 1

Joined: Oct 2003

04-24-2021, 09:04 AM

(This post was last modified: 04-24-2021, 09:15 AM by srv52761.)

(04-24-2021, 08:07 AM)JosephP Wrote: Yes...from main panel in barn to subpanel on other side of barn. Just trying to avoid needing to pull 100' of wire every time I want a new outlet of light. Not "necessary" now, but I thint it makes sense for the long-term.

On top of rafters...I meant the roof joist. This is a pole barn, so it is a 10' gap between rafters. May need to put a 2x4 between to run the wire on / provide something to attach it to? (Probably more expensive than conduit...but easier to run the wire).

The wire I linked in OP:

Allowable Ampacity 90°C (Amps) 155

Allowable Ampacity in Ducts (Amps) 115

Looks like SER has lower rating. MHF says 100 Amps. That is what the wire is rated for. Understanding local codes may say different...but no code here so as long as the wire can safely handle the load that is not an issue.

Appreciate the tips! Sounds like I should avoid conduit across the roof joists. I'll snap a pic or 2 when I am out there.

Main panel isn't even installed yet... They are doing that in 2 weeks. Meter is set on the pole and is on. 3" conduit from meter to barn is in ground and ready...so hopefully that goes quickly for them.

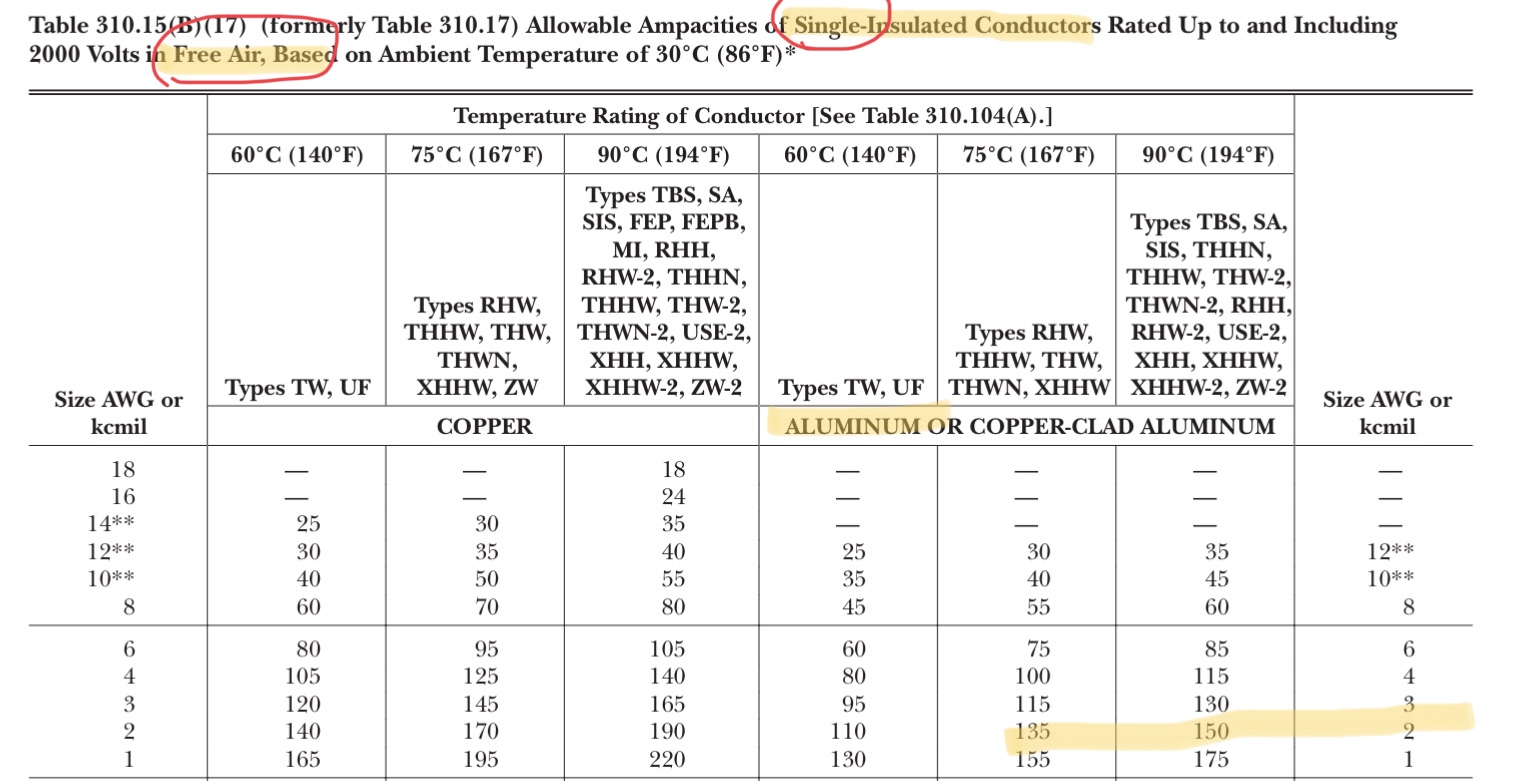

It looks like the guy who made that spec sheet for Nassau Electric used the wrong chart.

Ampacity goes way down when bundled or not suspended in free air as a single.

Additionally, the 90° column is used for derating purposes. The 75° column is used for running circuits. And you need to check your panel, both the main and the sub. If the termination at either is not rated for 75°, you have to drop to the 60° column.

(edit: Won’t be an issue, I don’t think they have made a 60° panel in the last 15 years.)

I could have been misunderstanding the applications for the last few decades, that has been known to happen.

Roly, Blackhat, or TDKPE are usually pretty current on code. Hopefully they will chime in.

If you go with SER, must be supported every 4.5’ at least and within 12” of box.

Posts: 19,076

Threads: 0

Joined: Jul 2002

Location: Ohio

Thanks srv52761! You clearly know more about this than I do so I'm not trying to argue just clarify...

The Nausau spec sheet includes "Use-2" which on the chart you provided is listed for 100A. I will check the panels (I already have the subpanel as it was recently installed in the built we tore down, so I saved it...) to see what temp rating they have.

I assume your chart is NEC? Is it correct to assume a specific cable can be rated to handle a load, but NEC still doesn't include that? Maybe that is the disconnect???

Posts: 22,729

Threads: 0

Joined: Feb 2005

Location: Regina Saskatchewan Canada

We have different codes here so I try to leave those specifics to others. Couple thoughts. A 2x6 run the length of the building on top of the rafter ties is a handy place to fasten all the wiring going across. 100 amps is a big sub panel for some lighting and convenience circuits in one end of a building. Use the panel you have but perhaps only feed it 60 amps?

Blackhat

Bad experiences come from poor decisions. So do good stories.

|