03-15-2022, 01:45 PM

I would nix buying a CRS bar. Most cold rolled steel comes .002- .005 undersized. The condition of the bar is determined by the condition of the rollers at the factory. Much like tires on a car. Run time verses cost. I made my own bar and fitted it to my miter slot about 25years ago. It worked great at the time, but there wasn't the after market fences that there is today. I fitted it to my miter slot at the time. It fit my saw then but it didn't fit the General I purchased a year latter.

IMO. plywood would be be a better choice for a runner than CRS. Solid wood works great if the grain runs straight up and down, see William Ng video on YouTube. Any after market fence's adjustable bar should be more that good enough. One can also purchase aluminum runner stock that is adjustable.

As far a using a penny all that will tell you is either the penny goes in the slot or it doesn't. I would start with an adjustable parallel and a Micrometer and then switch to my gage blocks to get the size and fits .The set consist of a .0500 block, a .1000 lock then .1001 -.1009 and then .101- .149 in .001 increments and then .150 followed by .200-.950 in .050 increments and then a I.000, 2.0000, 4.0000 and 6.0000 blocks . And the tolerance of each block is +or - .0000050 ( 50 millionths) at 68 degrees, heat sinked for 24 hours

Once you find out exactly what the width of the slot is and what is the perfect width so that you can get the sliding fit you desire then you can proceed to the surface grinder and fit the bar. Miss it buy .0005 and it will be to loose and .0005 the other way and the bar will not even go in.

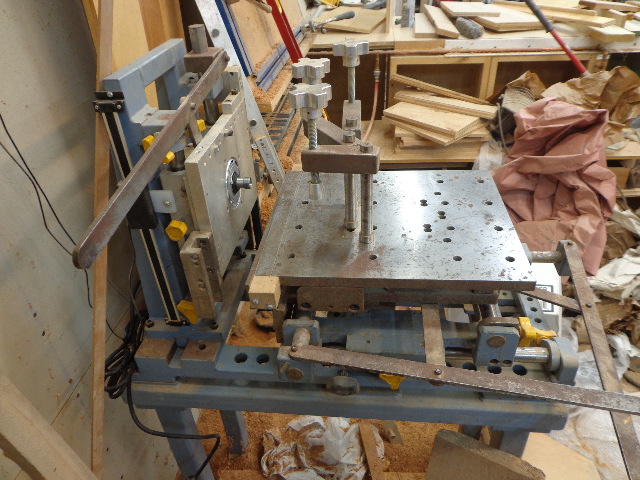

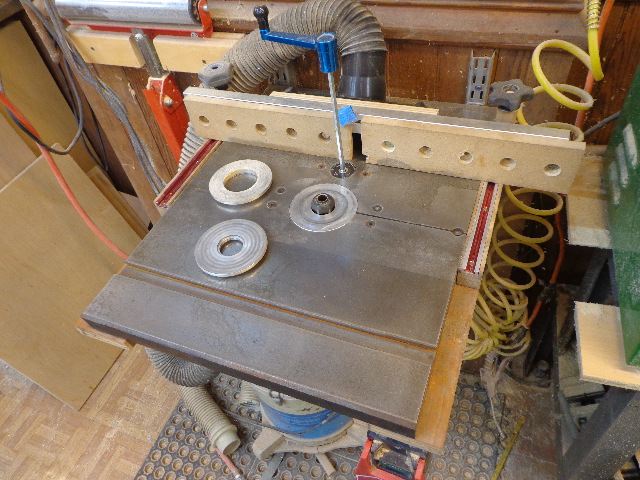

And it you wish to disagree with me please post pictures of you metal working ability as for proof of your abilities. I say this because I know how some of you are. Here are some of my spare time accomplishments to back up my abilities..

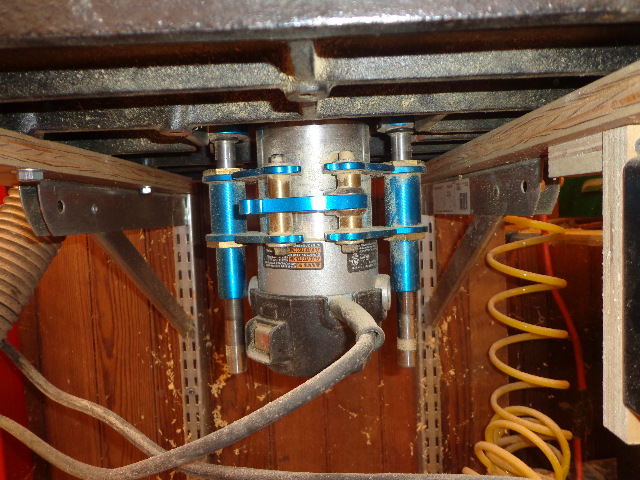

The last picture is a f a Delta tabletop drill press turned up side down. I mounted a gear reducing motor to the head with linkage, much like old rail road engines, so I could have a spindle sander that went up and down as well as rotating. I made it long before any one with a home shop one could buy a spindle sander. There wasn't any on the market yet.

Why did I write this? Because most of you have no actual knowledge or abilities to do what is being discussed here as far as metal working is concerned.

I am not trying to be nasty, but just to save you a lot of time and money. The best advise I can give is to watch a You Tube video by William Hg. ( Five cuts to a prefect cross cut sled.)

He has other videos about making runners also. His videos great as well as informative. When It comes to You Tube Videos I have great respect for Frank Klausz and William Ng. And not far behind these are Rob Cosman ,David Baran and a few others.

Tom

IMO. plywood would be be a better choice for a runner than CRS. Solid wood works great if the grain runs straight up and down, see William Ng video on YouTube. Any after market fence's adjustable bar should be more that good enough. One can also purchase aluminum runner stock that is adjustable.

As far a using a penny all that will tell you is either the penny goes in the slot or it doesn't. I would start with an adjustable parallel and a Micrometer and then switch to my gage blocks to get the size and fits .The set consist of a .0500 block, a .1000 lock then .1001 -.1009 and then .101- .149 in .001 increments and then .150 followed by .200-.950 in .050 increments and then a I.000, 2.0000, 4.0000 and 6.0000 blocks . And the tolerance of each block is +or - .0000050 ( 50 millionths) at 68 degrees, heat sinked for 24 hours

Once you find out exactly what the width of the slot is and what is the perfect width so that you can get the sliding fit you desire then you can proceed to the surface grinder and fit the bar. Miss it buy .0005 and it will be to loose and .0005 the other way and the bar will not even go in.

And it you wish to disagree with me please post pictures of you metal working ability as for proof of your abilities. I say this because I know how some of you are. Here are some of my spare time accomplishments to back up my abilities..

The last picture is a f a Delta tabletop drill press turned up side down. I mounted a gear reducing motor to the head with linkage, much like old rail road engines, so I could have a spindle sander that went up and down as well as rotating. I made it long before any one with a home shop one could buy a spindle sander. There wasn't any on the market yet.

Why did I write this? Because most of you have no actual knowledge or abilities to do what is being discussed here as far as metal working is concerned.

I am not trying to be nasty, but just to save you a lot of time and money. The best advise I can give is to watch a You Tube video by William Hg. ( Five cuts to a prefect cross cut sled.)

He has other videos about making runners also. His videos great as well as informative. When It comes to You Tube Videos I have great respect for Frank Klausz and William Ng. And not far behind these are Rob Cosman ,David Baran and a few others.

Tom