04-22-2017, 04:49 PM

Hello... I'm a new subscriber. Hopefully someone on this forum can help.

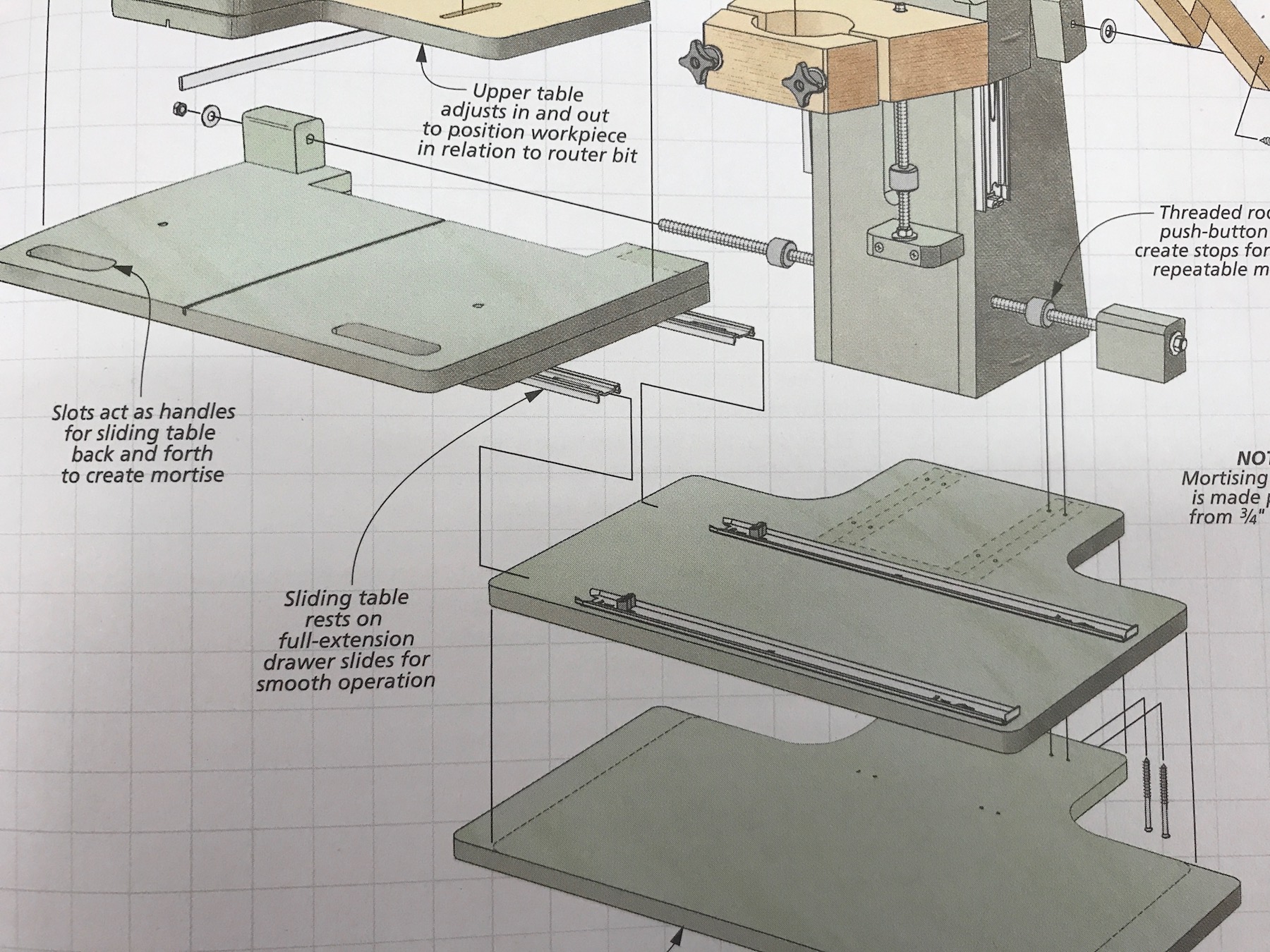

I have been building the router mortising machine, profiled in Issue 217 from Woodsmith. Got through all the steps, but I'm frustrated because I can't figure out how to attach the drawer slide to the base. I can attach one screw for each male end of the slide but not two, because the base prevents that. This is critical because it has to be fixed to be accurate. With only one screw on each male end, its sloppy.

Maybe the photo below can explain.

Almost finished

Two male ends of acuride slide. Can only attach one end because slide bed won't slide any further due to dog ears

From the plans, you can see the slides are supposed to be attached to the base, but I can't because when I go to attach the female to male, dog ears get in the way, and I have to tilt the bed to attach, and can only do that with one screw attached.

Thanks for your help.

I have been building the router mortising machine, profiled in Issue 217 from Woodsmith. Got through all the steps, but I'm frustrated because I can't figure out how to attach the drawer slide to the base. I can attach one screw for each male end of the slide but not two, because the base prevents that. This is critical because it has to be fixed to be accurate. With only one screw on each male end, its sloppy.

Maybe the photo below can explain.

Almost finished

Two male ends of acuride slide. Can only attach one end because slide bed won't slide any further due to dog ears

From the plans, you can see the slides are supposed to be attached to the base, but I can't because when I go to attach the female to male, dog ears get in the way, and I have to tilt the bed to attach, and can only do that with one screw attached.

Thanks for your help.

Home woodworker for over 30 years. The more I woodwork, the more I realize how little I know. This forum confirms it. You guys and gals are awesome.