Posts: 17,307

Threads: 0

Joined: Jul 2008

Location: Free At Last!

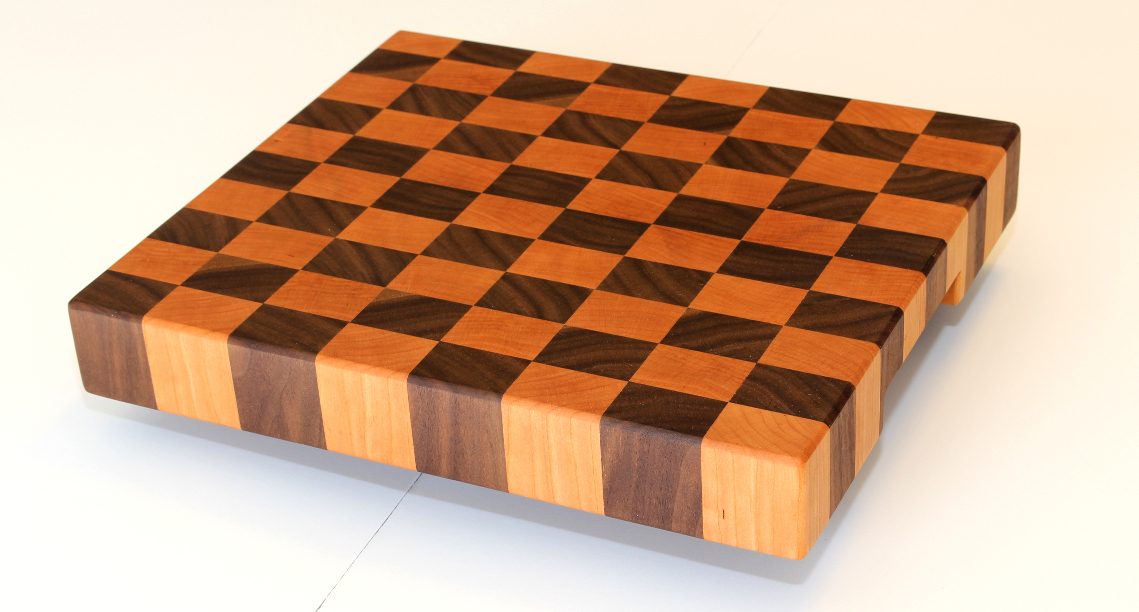

I haven't done any before, so I thought I would give it a shot. I can see how this becomes addictive.

Posts: 353

Threads: 0

Joined: Jan 2004

(12-22-2017, 12:08 AM)lincmercguy Wrote: I haven't done any before, so I thought I would give it a shot. I can see how this becomes addictive.

Very Nice!

Posts: 3,731

Threads: 1

Joined: Apr 2008

Nice! I haven't tried end grain cutting boards. I did make some similar to the one in the second picture.

There is no such thing as too much horsepower, free lunch or spare change ~ anonymous

87% of people say their mental health is good to excellent. The rest are sane enough to know they are lying. ~ anonymous

Posts: 16,604

Threads: 0

Joined: Oct 2002

Location: Ra-cha-cha, NY

I've always wondered, but never asked, how you sand a board like the third one without filling it with scratches, since the grain goes in different directions. My son wants to make a basket weave (sort of) pattern cutting board, but planing, scraping, or sanding without mangling the cross grain areas seems like a challenge.

Nice work, by the way.

Tom

“This place smells like that odd combination of flop sweat, hopelessness, aaaand feet"

Posts: 17,307

Threads: 0

Joined: Jul 2008

Location: Free At Last!

"I've always wondered, but never asked, how you sand a board like the third one without filling it with scratches, since the grain goes in different directions."

It's hard to see at this resolution, but the maple is end grain as well. I didn't think it would work too well to do it any other way.

For sanding, I built a v drum sander earlier this year. It works really well for this while keeping the surface flat. I sand with 180 grit on the vdrum sander. After that, I use a random orbit sander, working my way up to 240 grit.

Posts: 16,604

Threads: 0

Joined: Oct 2002

Location: Ra-cha-cha, NY

(12-22-2017, 10:22 AM)lincmercguy Wrote: "I've always wondered, but never asked, how you sand a board like the third one without filling it with scratches, since the grain goes in different directions."

It's hard to see at this resolution, but the maple is end grain as well. I didn't think it would work too well to do it any other way.

For sanding, I built a v drum sander earlier this year. It works really well for this while keeping the surface flat. I sand with 180 grit on the vdrum sander. After that, I use a random orbit sander, working my way up to 240 grit.

I zoomed in closer and I can now see that the border is end grain also.

We were thinking about something like this pattern.

The dark is oak, as I have a big slab of it at 1-5/8" thick (with some sort of finish, but which could be cleaned up to 1-1/2" thick) by something like 10" wide and 6 ft long. Lighter hardwood is probably maple (modeled at 7/8" square), with some other light-ish border wood. It could all be done using end grain if I made the 2"x4" dark sections a little smaller (1-1/2" x whatever), with other bits scaled as necessary.

I just don't have a belt or drum sander other than a hand held 3" Porter-Cable belt sander of the type I used to use when I worked in a cabinet shop as a kid. I own it, it's brand new as of at least 10 years now, and I've never even taken it out of the box.

I really should build a drum sander like others have done. I have a pile of small motors laying around, of course (doesn't everybody?).

Tom

“This place smells like that odd combination of flop sweat, hopelessness, aaaand feet"

Posts: 29,848

Threads: 0

Joined: Jan 2008

Location: Mid-MI

(12-22-2017, 10:22 AM)lincmercguy Wrote: I built a v drum sander earlier this year.

Got a tutorial?

Mark

I'm no expert, unlike everybody else here - Busdrver

Nah...I like you, young feller...You remind me of my son... Timberwolf 03/27/12

Here's a fact: Benghazi is a Pub Legend... CharlieD 04/19/15

Posts: 16,604

Threads: 0

Joined: Oct 2002

Location: Ra-cha-cha, NY

12-22-2017, 11:20 AM

(This post was last modified: 12-22-2017, 11:28 AM by TDKPE.)

(12-22-2017, 10:58 AM)CLETUS Wrote: Got a tutorial?

Found this one. Six video installments in total. Uses a 1/2 hp motor. Cheap and cheerful.

Someone did a build-along here not long ago. Don't remember who, though.

Found this, though it wasn't the thread I was thinking of. https://www.forums.woodnet.net/showthrea...id=7332143

Tom

“This place smells like that odd combination of flop sweat, hopelessness, aaaand feet"

Posts: 17,307

Threads: 0

Joined: Jul 2008

Location: Free At Last!

I thought I posted pictures of mine, but maybe I didn't. I'll do so when I'm on a computer again. I basically built a plan following the Stockroom supply plan with their kit. I also bought the motor they recommended since it was a TEFC for $100 and free shipping. Can't beat that.

Posts: 17,307

Threads: 0

Joined: Jul 2008

Location: Free At Last!

|