Posts: 4,132

Threads: 0

Joined: Nov 2010

In theory, yes. Have a stack of 4/4 x 6" x 54" Ash planks...

Pick one plank, because it was free of warp, free of knots, free of live edges....and as straight as I could find...helped that the grain wasn't too "plain", either..

Project? Well Simon's hero, Paul Sellers, is doing a build-along video...an "Organizer". So, signed up, and downloaded the plans ( all free, I like that part

)

Moose and Squirrel had to fight their way through my printer, past Boris and Natasha...to deliver 4 pages...

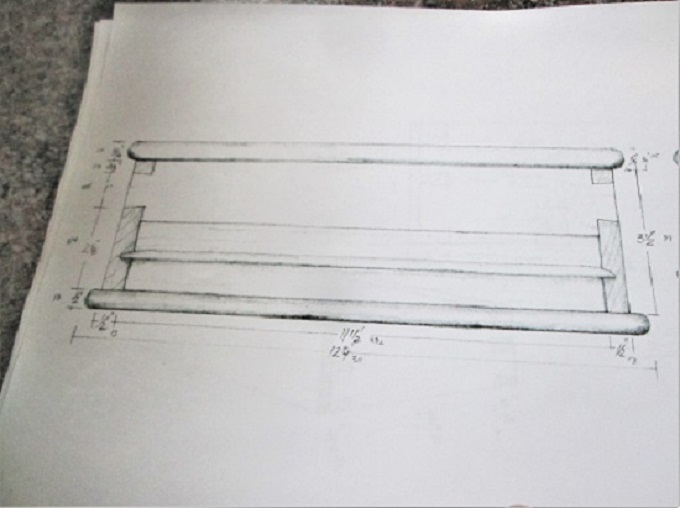

A "Front View"...

A view of one of the ends...

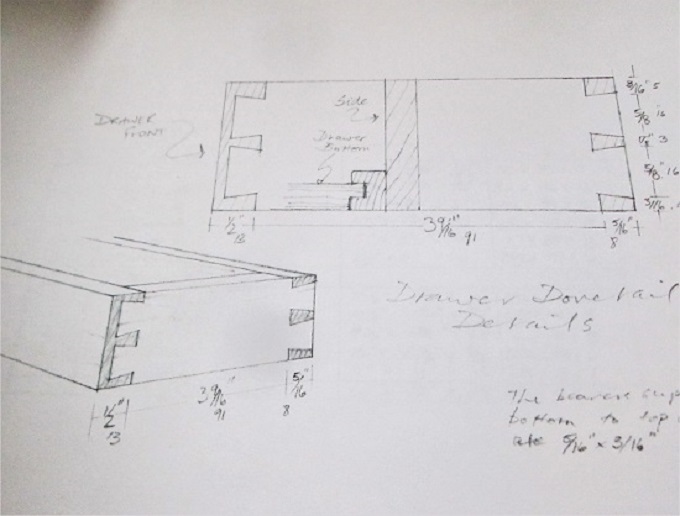

Drawer details ( Paul does drawers a bit different than me

)and....

The ever important Cutting List.

So, I guess I had better start making sawdust?

Stay tuned

Show me a picture, I'll build a project from that

Posts: 2,775

Threads: 0

Joined: Oct 2012

Location: W. of Rainier, E. of Orcas

Are you sure this will be only one 54" plank? I think the last one started with "scraps" that grew.

Just keeping everyone honest....

Posts: 5,351

Threads: 0

Joined: Jan 2014

Location: Santa Maria, Ca

Another Bandit build along!! Cool!

Mark Singleton

Bene vivendo est optimum vindictae

The Laws of Physics do not care about your Politics - Me

Posts: 4,132

Threads: 0

Joined: Nov 2010

Lets see...plank was hauled to the shop...

Had to clear the deck for action, was a bit too full..

Even had to put some things away

to get a bit more elbow room..

Plans laid out...Disston D-8, 11ppi for the crosscuts ( tried the Atkins 65...like the D-8 better) laid out the first cut..

And got busy with the Cardio Workout...

Was hoping to get enough leftover, for both the base and the lid....usual luck..

Was enough for either, but, not both...so, this is either the lid, or the base of the box...

I need to joint both edges, and will be just wide enough...however...plan says this needs to be 11/16" thick...

caliper says I am at 0.998" thick.....might have to plane this a bit?

Cardio over, for now....need to rip the other boards for width...

These will be the front, the back, with the shorter one being cut into the 2 ends...I jointed one edge, then set the rip fence on the tablesaw to a tad wider than needed...then, reset to a hair wider than finished width....except for the piece going out front. When placed together after they have been sawn into 2 halves, they still have to match the width of the back and ends pieces....more fence adjustments..

Ok, problem here? These pieces need to be 1/2" thick....not 0.998"....so, next episode, I take care of that...

Stay tuned

Show me a picture, I'll build a project from that

Posts: 4,132

Threads: 0

Joined: Nov 2010

To get from 0.998" down to about 0.500", I need to resaw a bit off. Plan was to rip the worst face off, leaving the better one intact, to be smooth planed...reset the tablesaw and the fence...blade as high as it will reach ( lowered it for the 2 narrower ones) and set 9/16" away from the fence...

height of cut barely reached to the mid point...on the wider two boards...

Which left a ridge down the middle to plane away...

But, blank is at 0.520" thickness. I did save the thinner "cut-offs" for other things...but,

All 4 pieces are ready for the #3 smooth plane. Box needs a wood floor, between the drawer and the storage compartment above it....found a bit of Poplar

That might be the right size....may use some of the other cut-offs...

For drawer parts? May have spent a little over an hour in the shop, today....may try again after Supper?

Stay tuned..

Show me a picture, I'll build a project from that

Posts: 4,132

Threads: 0

Joined: Nov 2010

Ok, will try to get this caught up..

Used a Millers Falls V-Line smoother ( #4 size) to smooth things out..

Couple needed jointed, to match up with the rest..

Squared things up, cut one board down to make the two 5" long ends. Found a couple thinner sticks...

To make drawer sides and a back with. let these sit a while....

Ok, next shop session. Cleaned the top of the bench off...and dug out the dovetail tools..

Layout toys, and such.....backsaw was put to work, though..

Not a big fan of "tails first", but the plan and video call for it....Mr. Witherby stopped by...

To help out on the tails....

But, I got better as the day wore on

Until..trying to do the second end piece....had a split fly apart...had to go back and re-do the end from scratch...finally..

Able to do a dry fit (no glue, yet) clamped up to keep things together...

The "good" end. This mess took about 2 of the 3 hours of shop time, yesterday....be back later, to tell about the rest

Stay tuned

Show me a picture, I'll build a project from that

Posts: 4,132

Threads: 0

Joined: Nov 2010

01-17-2020, 12:13 PM

(This post was last modified: 01-17-2020, 12:16 PM by bandit571.)

Ok..remember this plank?

A little rough around the edges...and too thick...

0.998" is a long way from 11/16". Ends needed squared up and to length of 12-3/4". Edges needed buzzed to 5-3/4" for a width....AND parallel...Then set up the tablesaw to 7/8" between the blade and the fence. Problem being, even with the blade raise all the way up, it still won't reach the middle of the board...

Ran all 4 edges through. Resaw at the bandsaw to remove the waste....had a 1" wide strip down the middle...

That will need planed down. Set the board under the dry fit, to check how it will look..

Clean it up, smooth the underside....might just do..

Task today, after a late Lunch?

The upper half of this box needs a floor, to keep things from falling into the drawer. I need to plough a groove to house the floor, then cut the floor to fit, and then, maybe, do a glue up....we'll see....

May even start on the drawer?

May need an entire day in the shop for that...but, after a 3 hour stint in the shop, it was time to hang things up..

Stay tuned.... the cussing has begun

Show me a picture, I'll build a project from that

Posts: 4,132

Threads: 0

Joined: Nov 2010

First a rebate, to house the storage compartment's floor..

Needed this, to lay out the other grooves, for this plywood panel to sit in...

Meant I needed to move a fence a bit...

Then had to move it again, because I went up, instead of down,,,,

Got all the grooves done...dry fit?

This is the underside of the "floor", topside?

Ok, glue and clamp time next..

And, check for square...

Set this aside...had to plane the base flat...

Had to resaw it, to correct a spot..then a plane to level the playing field..

Until it looked presentable...

I also had Laundry Detail to do....sweep the shop floor after making a big mess of shavings...and even planed the back and side parts for the drawer...then hung the apron up...and closed up for the day..

.

Stay tuned...the cussing has begun...

Show me a picture, I'll build a project from that

Posts: 4,132

Threads: 0

Joined: Nov 2010

Ok...box came out of the clamps...did a bit of clean up

Plane and the sanders..trying NOT to split out a tail, or two...

Well, I at least tried....now, about that botom panel, I call a Base...needed round overs...Sellers used a plane..

And a sand paper smoothing...I guess I can too...end grain first..

Then the long grain edges...Sanded all down...( helps if I mark a center line first. ) Sellers marked where the box will sit, centered on the base, marked a line to follow, and avoid when doing the round -overs....Then..he simply glued the base to the box...

Just going by his plan. Up front, where the drawer goes...I had a bit of splay going on....needed to pull things back into line..

We have ways....

This morning...clamps came off. Last night, had the 7 planks left planed down to about 3/4", or so....will go through the stack...looking for the best grain for the lid.

Once That is cut to size....I need to plane a rebate around the underside. Set for the hinges to be used. Then the round-over around the edges of the lid...

need to size the drawer front, and the sides and back of the drawer....Sellers used "slips", I'll use a groove....stay tuned

Show me a picture, I'll build a project from that

Posts: 4,132

Threads: 0

Joined: Nov 2010

01-21-2020, 09:01 AM

(This post was last modified: 01-21-2020, 09:05 AM by bandit571.)

Well, out of the 3 candidates, #2 won out...

So, hauled it to the shop, Charlie Horse cramps and all...I picked the best behaved section, and marked out for the lid. Idea being to be a bit oversized, to allow for any trimming for square.....needed 5-1/2" width..board was 6-1/4" wide..

Figured the Disston D-8 was enough for the job....26" length, 11 ppi....even the operator was cutting straight....problem? Like a tree, board was tapered a bit along it's length...trick was to get rid of the taper. 12" Stanley #20 square, mark 2 lines..

Side with the least to plane away, was jointed straight, then that edge went against the tablesaw's fence, where I discovered the blade had a 3 degree tilt. Fix that, then planed off the saw marks. Box came out of the clamps..

with issues...

Which I will try to do later, today. Back to the lid....Sellers used a rebate around the underside of the lid, more to clear the barrels of the hinges...might as well do it all the way around...plus a round over...to match the base...( cheated on the round over a bit, roughed out with the router bit, final shape with the #3 plane)

Sellers and I used the same plane to mill the rebates, except..the spur was used on mine.

Small hinges, maybe too small?

Will have to see what else I have in the hardware spares box....sit the lid on the box, for now..have a drawer to cobble up..

.

Parts are sitting, waiting to get sized.

hardest part was getting things to slide in and out easily..

Back had to wait a while. It was cut to size after the grooves for the bottom were milled, then was fitted to the sides in dados...test drive?

Mainly to see if the drawer would slide in...before I did any glue up....that will be the next episode..

Stay tuned...

Show me a picture, I'll build a project from that

|

)

)

)and....

)and....

)

)

)and....

)and....

That will need planed down. Set the board under the dry fit, to check how it will look..

That will need planed down. Set the board under the dry fit, to check how it will look..