02-04-2021, 01:16 PM

Depending on the chisel and its intended purpose, the hardest or most time consuming part is flattening the back.

My grandson asked me how I sharpened chisels and said they used Work Sharp. He is in ninth grade.

I also read a post here about CBN wheels for a Work Sharp. Some said they wouldn't use them because of what they had read about gumming up because older tool steel wasn't as hard. Some liked just using the type of abrasives that came with it. Sighted cost as a factor, but CBN could be cheaper in the long run. There were also many other differing opinions also.

To me the most time consuming part it getting the back flat. I asked here if anyone flattened on a work Sharp. Some did, all of the time, and others wouldn't even consider it. My disclaimer is I do not have a Work Sharp, not do I plan to. I read or found out somehow that that it rotates at 350 RPM on getting one. Anyway I know the hardest thing to do is put something up against a spinning disc without messing up part of the piece . The piece is either tilted side to side or front to back or both. And the faster the disc spins the more initial problems occur.

Anyway I have CBN wheels on my bench grinder and I haven't found the loading up to be a problem. At least a problem that can't be fixed with a small brass ( steel in a pinch) brush and about 30 seconds. .

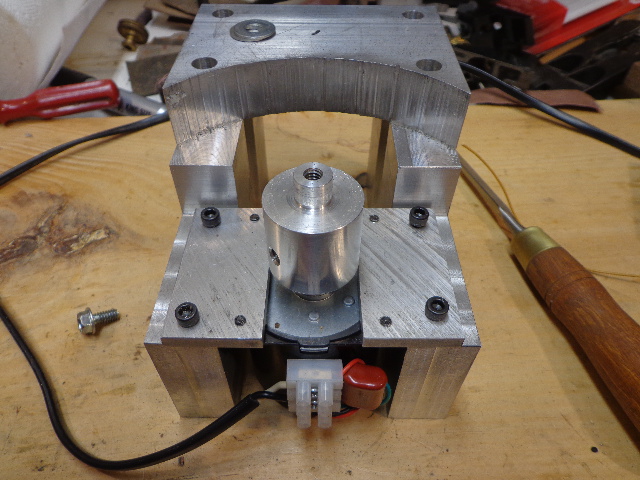

Anyway this is what I came up with. A 60 RPM gear reducing motor. I made the adapter for the 80/180 CBN disc.

The motor is reversible ( and will be awesome ) But I haven't wired it that way yet. I haven't even mounted it yet. My friend always reads nameplates and commented it can over heat is run for a long time. And since he s in electronics he gave me a fan so I have to get it wired in also.

I am not finished with it yet but I have tried it out and I haven't had a heat problem yet.

I can stall out the disc if I use to much pressure on the chisels. Which is good pressure puts deeper scratches in the steel

I worked between a 1000 grit diamond stone and the 80/180 CBN wheel and I flattened two Narex chisels I am in the process of making specialty chisels, Dove tail chisels butt more on those later.

At real slow speed the CBN wheel tends to load up and you can feel it while working but the wire brush takes care of it in 10 seconds or so. I clean it with it turned off.

Getting on and off the wheel is a piece of cake. not problems what so ever.

Anyway pictures

I like the way it works and right now I am trying to decide if getting a finer grit disc or just take the deeper scratches out by hand . I have already designed my leather disc in my head. Will glue the leather to a 1/8 aluminum disc.

I am sure there will be questions and comments so I will keep this a little short.

Tom

My grandson asked me how I sharpened chisels and said they used Work Sharp. He is in ninth grade.

I also read a post here about CBN wheels for a Work Sharp. Some said they wouldn't use them because of what they had read about gumming up because older tool steel wasn't as hard. Some liked just using the type of abrasives that came with it. Sighted cost as a factor, but CBN could be cheaper in the long run. There were also many other differing opinions also.

To me the most time consuming part it getting the back flat. I asked here if anyone flattened on a work Sharp. Some did, all of the time, and others wouldn't even consider it. My disclaimer is I do not have a Work Sharp, not do I plan to. I read or found out somehow that that it rotates at 350 RPM on getting one. Anyway I know the hardest thing to do is put something up against a spinning disc without messing up part of the piece . The piece is either tilted side to side or front to back or both. And the faster the disc spins the more initial problems occur.

Anyway I have CBN wheels on my bench grinder and I haven't found the loading up to be a problem. At least a problem that can't be fixed with a small brass ( steel in a pinch) brush and about 30 seconds. .

Anyway this is what I came up with. A 60 RPM gear reducing motor. I made the adapter for the 80/180 CBN disc.

The motor is reversible ( and will be awesome ) But I haven't wired it that way yet. I haven't even mounted it yet. My friend always reads nameplates and commented it can over heat is run for a long time. And since he s in electronics he gave me a fan so I have to get it wired in also.

I am not finished with it yet but I have tried it out and I haven't had a heat problem yet.

I can stall out the disc if I use to much pressure on the chisels. Which is good pressure puts deeper scratches in the steel

I worked between a 1000 grit diamond stone and the 80/180 CBN wheel and I flattened two Narex chisels I am in the process of making specialty chisels, Dove tail chisels butt more on those later.

At real slow speed the CBN wheel tends to load up and you can feel it while working but the wire brush takes care of it in 10 seconds or so. I clean it with it turned off.

Getting on and off the wheel is a piece of cake. not problems what so ever.

Anyway pictures

I like the way it works and right now I am trying to decide if getting a finer grit disc or just take the deeper scratches out by hand . I have already designed my leather disc in my head. Will glue the leather to a 1/8 aluminum disc.

I am sure there will be questions and comments so I will keep this a little short.

Tom