Posts: 4,006

Threads: 0

Joined: Nov 2010

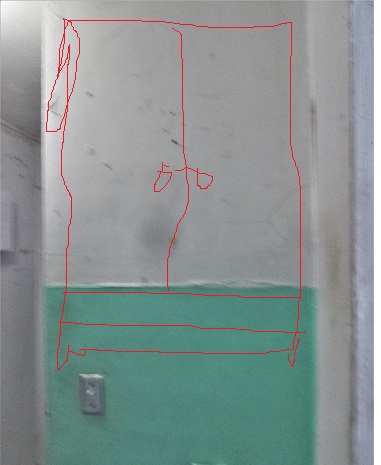

Have an ugly blank space..

Right behind the toilet....not much better looking to the side...

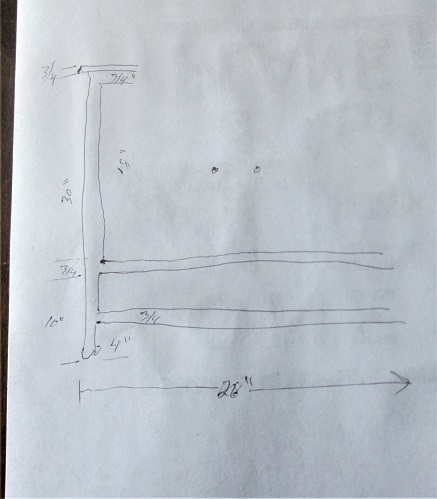

Need to leave access to that light switch, too.....Single Brain Cell Sketch Up is up and working, again..and came up with a sketch to start from..

That I can modify as things evolve....mainly in the width of the cabinet....and a middle shelf....and a pair of raised panel doors....bottom corners have a rounded detail..

Just in case I want to add a hand towel bar.....Lumber supply?

nine Ash boards....random lengths 1 x 6s....

Thinking this long one could be made into a pair of matching raised panels? Need to rip some for the frames to go around them...

Well, that be the start.....stay tuned...

Show me a picture, I'll build a project from that

Posts: 2,724

Threads: 0

Joined: Dec 2005

I have a similar wall cabinet hanging over the back of the "throne". Word of caution: the wall behind the throne often houses a vent pipe, 3" or 4", that runs vertically behind the toilet. Keep that in mind when you are attaching the cabinet to the wall: drilling into a vent pipe might just ruin your whole day!

Posts: 4,006

Threads: 0

Joined: Nov 2010

02-10-2021, 05:57 PM

(This post was last modified: 02-10-2021, 05:58 PM by bandit571.)

This wall does have a single stud running in the middle of that area....there is a pipe for the shower attached to that....Figure to hang the new cabinet with a pair of "L" brackets screwed to that stud.

Shelves:

2 of Ash, one is a 1/2" thick Pine shelf for inside the cabinet.

Sides (2) have that curvy profile at the bottom

Sides also get a few dados...

And the top of the cabinet also gets 2 dados...

front corners of the top a rounded...and the top planed smooth..

Then all of the parts get stacked up, for now..

Until I can set up for a dry fit...

Top will have to wait a bit...

Until I do a glue up....kind of hanging out in the middle of nowhere...

Now, IF you want to read the rather boring story of milling all them dados....

Until then, waiting on the glue up to happen...stay tuned

Show me a picture, I'll build a project from that

Posts: 4,006

Threads: 0

Joined: Nov 2010

Hmmm....Dados....a blend of old and new....

Laid out ...

using the actual shelf thickness....then set the tablesaw height to 1/2"....

make a bunch of cuts, trying to just nick the lines. Had to recheck the mitre gauge, was a "tick" out of square...then..

Either a chisel, or a wide screwdriver to break the waste out....could of used a hammer...but, it tends to leave dents....

Rough "floor" of the dados? Old school router...

Nice when you can come in from both directions, to avoid any blowouts...

Then try a dry fit...

Middle shelf...used 1/2" thick pine...so, dado needed to be narrower...

But still 1/2" deep. Dados to attach the top to the cabinet...

Were set 1" in from the ends. Front corners were bandsawn

And, since the top had a slight bow across the width...

A Sargent VBM No. 414c was used to flatten things out.

Everything is set up to do a glue up....

Stay tuned...cussing WAS involved....

Show me a picture, I'll build a project from that

Posts: 4,006

Threads: 0

Joined: Nov 2010

Glue up? Well...I had gone to the shop ( on a Monday?) just to see how things would all dry fit together...and lay out a bunch of clamps...didn't even bring the bottle of glue along...

Was trying to figure a way to glue this mess together...went and got the bottle of glue....

Thought if I stood this up, I could use the clamps a bit easier....had to pull the tablesaw/assembly table way out, to where I could access both the back and..

A couple clamps thought they were "Sabres"...

yeah....real fun was adding the top to this mess...

Finding enough clamps to go the full length and then reach around the clamps already sticking out there...

Found 2 long clamps....had to use another way for the other 2. Thought I could clamp onto a shelf....seemed to work...until the shelf started to bend a bit.....added clamps to remove that bend...and any others that wanted to start....

Been letting this sit a day or two.....have to be careful when removing that forest of clamps......lest thing fall over (onto the floor

) or things fly back apart

But...I need the tablesaw back....these parts..

Well the top board is now a shelf....the other 3 need ripped down into frames to build 2 doors.....I also need to glue up a pair of panels...to make the raised panels for the doors.....need to find a place to sit the glue-up while I work on the doors....

Stay tuned..

Show me a picture, I'll build a project from that

Posts: 9,536

Threads: 0

Joined: Jan 2005

Location: Orlando FL

This is coming along quickly. Sometime you will have to go over your planning process and give us analysis paralysis people some pointers. I spend more time looking at options than I have to get things done.

Posts: 4,006

Threads: 0

Joined: Nov 2010

"Process" is all done in my head...rarely even use a paper plan. Things get adjusted as I go along.

So, update time? Clamps did come off the case,,,no real problems...

Except for...

This is that skinny, Pine shelf....it is flush with the front of the case, no problem with that....however, it is supposed to be flush with the back, too...

We have ways...then a place to sit this case...while I mill other items....

Yes, the case is indeed square...those gray legs behind the case are splayed out, to support the bench. Set up a rip fence...have parts to mill..

Then run a few boards through, at 1-1/2" or so wide...

Might be enough? They are a tad thick, though...

7/8" thick....yeah, will come back later, and thin these down..to 3/4" thick...next, well, I wanted that long plank for the raised panel blanks, hopefully I could get all 4 blanks from it...

Nope, usual luck..#4 was 4" too short..

So, trudge back upstairs, grab the best one of the 3 still left up there...cut around the knots and splits...wound up with 2 decent blanks..

And a third "good" one, and the extra blank...

Hmmmm. this might take a wee bit of work...

Set things aside for the night....later, see about thinning those 1xs....and get two panels glued up?

Stay tuned..

Show me a picture, I'll build a project from that

Posts: 4,006

Threads: 0

Joined: Nov 2010

Came back a little later ( got bored just sitting around, again)...set up the rip fence....goal being to straighten a few edges...at least enough to then joint the edges and glue two panels up...

had to straight-line rip one edge, then reset and rip the other edge as well....as all four had a taper. Some fine tuning with the jack plane as a jointer...then a bit of glue a caul, and a few clamps...

Let these sit right here, until called for.

Now, about those fat slats....reset the ripfence....blade all the way up, 3/4" between the blade and the fence. Not a fan of having fingers in that area...kind of cramped, so...

We do indeed have a pushstick...or two....this one is for the skinny stuff...just an old saw handle, and a bit of 1/4" plywood....with a notch...as long as the handle can fit through there....we good to go..

Found a couple others to add to the pile.....will sort through and pick out the best of the mess.....letting these sit a day, to get used to being milled...

Stay tuned

Show me a picture, I'll build a project from that

Posts: 4,006

Threads: 0

Joined: Nov 2010

02-14-2021, 11:52 AM

(This post was last modified: 02-14-2021, 11:55 AM by bandit571.)

Went and sorted through the sticks...found a couple decent ones, that were long enough to make the 4 rails....and another four that can make the 4 stiles..

They all needed a little cleaning up, whether with a jack plane

To remove the rough sawn edges, and any curvy stuff...or..

gang up the 4 stiles and cut them all to the same length...needed a jig made, too

Just 3 scraps of thin (1/2" ) Pine...then add a couple notches...

To better hold these stiles and rails until I can get some grooves milled....

With the Stanley No.45...and the #12 cutter...of course, with the rails being a bit shorter..had to adjust the jig a bit..

Set up a combo square to check on how the depth is turning out...

There would always be a "high spot" in there, somewhere...still...it didn't take all THAT long, until..

All 8 grooves were done....but...I wanted to mill some beads, too...needed to sharpen the #22 cutter first...

And set up the Stanley #45 to do beads....and reset the jig...again

Stay tuned

Show me a picture, I'll build a project from that

Posts: 4,006

Threads: 0

Joined: Nov 2010

02-14-2021, 12:19 PM

(This post was last modified: 02-14-2021, 12:21 PM by bandit571.)

Besides being good as a plough plane...the 45 can be set up to mill beads..

Move the skates to match whatever cutter (hopefully a sharp one)...and move the fence to match,,,depending on where IN the board you want the bead to appear...

Also, it is nice to set up a test strip...to see IF the bead looks the way you want it to....then set up the jig..

Depending on the grain directions in this Ash...cut need to be as light as I can get it to cut...and not dig in...because..

Each stile or rail gets 2 beads....Jig wanted to fight a bit...did the rails first..

All four rails = 8 beads....had one item that had a high spot right in the middle of the edge...was trying (very) to bend into a curve...we have ways..

Few more passes...no more hill...

Reset the jig, again...for the longer stiles..

Until this last bead was done. Old candle to help the plane slide along...220 grit sandpaper to clean up when each bead was done...

Next? Well, it involves these..

And these 2 saws...

And....this other saw..

As to join the corners, I need mitered half lap joints.....

Stay tuned..

Show me a picture, I'll build a project from that

|

) or things fly back apart

) or things fly back apart