08-29-2021, 05:26 PM

Here are some pictures of the bench I am just finishing up.

It is a hybrid Roubo, given the fact the top sets on the legs and that the legs are not mortised into the top. I really like a split top in that it allows for a lot of options not found on a just flat top. For instance in the back ground of the first picture is an insert that, for the most part, be flush with the top. It will slots in in it for sticking chisels and things in and yet can be raised raised up for a planning stop like on a Mickelson bench. It is 4 hands high, 94 inches long and 24 inches wide and the top is 3 5/8 inches thick The top is southern yellow pine and the legs are walnut. Southern Yellow, Ash and Douglas fir will absorb blows, Hard maple, red oak and a few others will allow bounce back. The split top allows me to basically place the board on the bench to look over, decide what parts the board is going to be used for and Also it allows me to hold and support both ends of wood that needs to be cut down to rough length. No going to the chop saw , saw horses or pieces that need to be picked up off from the floor.

The next picture is of the leg vise yet to be sculptured. And the second shows correct clamping procedures. The top of the vise is against the side of the bench and the bottom of the vise is 3/8 away from the leg. The top's side is flush with the leg.

The vise screw is almost to the top so the clamping force is applied to the piece being clamped. It is plane physics, The clamp should be lower at the place it clamps and higher on the other end and the clamping force, in this case the vise screw should be as close as possible to the part being clamped other wise the exact opposite becomes true. the stand off and if it is pictured in the opposite direction the like clamps are shown in catalogs the part being clamped

The next is the correct way to clamp and then it goes from bad to worse. Recognize some of the clamping in catalogs.

And for your information all is this is engineered into Bench Crafted's screws and Criss cross. His vise hardware, hence vises, clamp solidly because he got all the clamping principals correct. He has done it right, and good for him.

Next is this bench has 3/4 drilled holes for round dogs. The threaded rod and handwheel is for a yet to be built moxon vise that sets on and is held on with nuts ,no extra clamps needed.

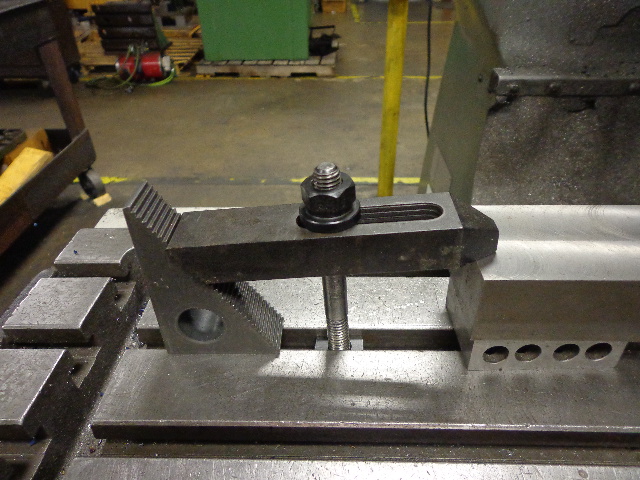

And next is the wagon vise with a purchased dog . Sliding dead man yet to be built.

I used to hold fast which I had a friend who black smiths make for ne out of a tire iron. The hold fast really takes a 5/8th hole. although it works I need to get some different ones.

The bench basally brakes down in about a minute with help. Getting to old to lift the one top piece which is 13 inches wide.

I have a lot more to say on design. styles of bench vises, and so on. So I hope to get a lot of good feed back. And by the way I prefer Scandinavian benches, shoulder vises, tail vises, and square dog holes. I think Roubo benches and leg vises are over rated, so I am really out there on this one. I have a lot more pictures of other work holders so I am just giving you a heads up.

PS: I figured out a better way to make a bench mobile than using the casters from Rockler. The bench is to long and the bench becomes very hard to keep even somewhat in a straight line.

Tom

It is a hybrid Roubo, given the fact the top sets on the legs and that the legs are not mortised into the top. I really like a split top in that it allows for a lot of options not found on a just flat top. For instance in the back ground of the first picture is an insert that, for the most part, be flush with the top. It will slots in in it for sticking chisels and things in and yet can be raised raised up for a planning stop like on a Mickelson bench. It is 4 hands high, 94 inches long and 24 inches wide and the top is 3 5/8 inches thick The top is southern yellow pine and the legs are walnut. Southern Yellow, Ash and Douglas fir will absorb blows, Hard maple, red oak and a few others will allow bounce back. The split top allows me to basically place the board on the bench to look over, decide what parts the board is going to be used for and Also it allows me to hold and support both ends of wood that needs to be cut down to rough length. No going to the chop saw , saw horses or pieces that need to be picked up off from the floor.

The next picture is of the leg vise yet to be sculptured. And the second shows correct clamping procedures. The top of the vise is against the side of the bench and the bottom of the vise is 3/8 away from the leg. The top's side is flush with the leg.

The vise screw is almost to the top so the clamping force is applied to the piece being clamped. It is plane physics, The clamp should be lower at the place it clamps and higher on the other end and the clamping force, in this case the vise screw should be as close as possible to the part being clamped other wise the exact opposite becomes true. the stand off and if it is pictured in the opposite direction the like clamps are shown in catalogs the part being clamped

The next is the correct way to clamp and then it goes from bad to worse. Recognize some of the clamping in catalogs.

And for your information all is this is engineered into Bench Crafted's screws and Criss cross. His vise hardware, hence vises, clamp solidly because he got all the clamping principals correct. He has done it right, and good for him.

Next is this bench has 3/4 drilled holes for round dogs. The threaded rod and handwheel is for a yet to be built moxon vise that sets on and is held on with nuts ,no extra clamps needed.

And next is the wagon vise with a purchased dog . Sliding dead man yet to be built.

I used to hold fast which I had a friend who black smiths make for ne out of a tire iron. The hold fast really takes a 5/8th hole. although it works I need to get some different ones.

The bench basally brakes down in about a minute with help. Getting to old to lift the one top piece which is 13 inches wide.

I have a lot more to say on design. styles of bench vises, and so on. So I hope to get a lot of good feed back. And by the way I prefer Scandinavian benches, shoulder vises, tail vises, and square dog holes. I think Roubo benches and leg vises are over rated, so I am really out there on this one. I have a lot more pictures of other work holders so I am just giving you a heads up.

PS: I figured out a better way to make a bench mobile than using the casters from Rockler. The bench is to long and the bench becomes very hard to keep even somewhat in a straight line.

Tom