Posts: 4,213

Threads: 0

Joined: Nov 2010

Ok, normal hardwood supplier is on Holiday, to see his Daughter down under in Sydney,AZ....be back sometime near March. Went to Lowes, to find a few more of those Craft/Project boards in clear Pine...1/2" x 6" x 36".....at about $7 each.....of course, they were out of stock. A glance at the Poplar ones was more than enough to just walk on past...which left the Red Oak ones....OUCH! 1/2" x 5-1/2" x 48" = $22.98.....each. there were 4 in the rack...3 weren't bad, the 4th would have made a good hunting bow.

10% Military Discount made things a tiny bit better...

And..

Plus one had some decent grain..

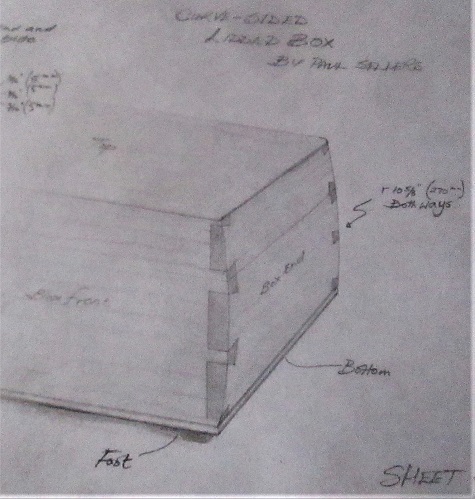

Was looking around for some ideas on how to use this gold-plated stock.....stumbled onto Paul Sellers Master Class videos...Thought maybe I could try a version of his Keepsake Box with curved sides Project. Since I am logged onto his Free version...decided to down load the plans..

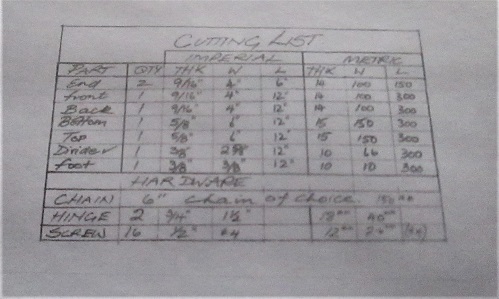

Came in 3 pages..

Third page even had a cut list I could follow..

Although, my stock is a bit thinner than Paul used....will have to adjust, is all..details?

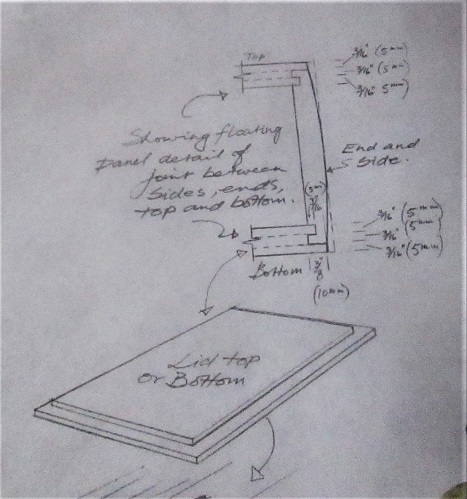

All sorts of curves. top and bottom panels float..

And the lid gets sawn off, after the glue-up..

So...looks like I have my work cut out for me....might have to buy different hinges...

As these might be a bit too big....

Stay tuned...

Show me a picture, I'll build a project from that

Posts: 4,213

Threads: 0

Joined: Nov 2010

First off, needed to "clear for Action" as the bench was a bit....messy...

So....

Tools NOT needed were put away...(yes, this IS my workbench..)

Cleaned out the Tool well.......first time in how long? Didn't last, as the tools I will need to use..

Wandered over to the open area....which left those pencils and the sharpener to put away....then the Lumber had a place to land on..

Keep in mind...these boards are just 48" long.....

Soon to be a bit shorter, though. First order of business after Lunch, today....is to cross cut a few boards for length..

Usually this gives me perfect 90 degree cuts. Need 2 sides, 2 ends, and then see about the 2 panels....

Stay tuned...waiting on Lunch to settle through...

Show me a picture, I'll build a project from that

Posts: 4,213

Threads: 0

Joined: Nov 2010

Laid out some crosscuts, today..

Goal was 2 sides at 12", and two ends at 6"...plus remove a bad end from the board....all from one plank..

1st cut included that bad section..

2nd cut took that away..couple more cuts...

There was a problem, though....these are 5-1/2" wide...plan only calls for 4"....set up the rip fence..

Set a tad wide, rip off the worst amount..then joint the sawn edge..

Then reset the fence to 4"...and run the jointed edge along the fence....next? According to the plan..

The ends get a shallow rebate on the inside face. 3/16" deep x 1/2" wide (thickness of the boards I'm using)...lay that out. Even set up the Stanley No. 71-1/2 to 3/16" depth, and used that to mark the end grain.....Mitre Box to make a cut...

A sharp, wide chisel to pop most of the waste off...

Then, remember that router plane?

Clean things up with it..working in from the edges towards the center....one done. Just repeat for the other 3 rebates

Stay tuned, the "fun" is just beginning..

Show me a picture, I'll build a project from that

Posts: 4,213

Threads: 0

Joined: Nov 2010

Complicated part comes next...tails for the dovetail corners...

That have to follow the curved sides of the box...

Looks like "fun", don't it? On the plan, it calls out the spacings for the tails....

Helps to keep the plan handy. Ends are marked as to inside face(rebate) and top and bottom edges...as the spacing is a bit different near the top..to allow the lid to be sawn off later....Tails use either a 1:6 or a 1:7 angle ( MK2 Eyeball) ..BUT, there is one other line to mark....the baseline is NOT a straight line. Sellers uses a 11mm:1mm angle..that angles up towards the center. Tried to come as close to that as I could...then saw down just to the angled line....with me so far?

Once the saw work is done, then chop out the waste...

And it should look something like this. One done, now, repeat for the other 3 ends...

This was about 3:30 this afternoon...back is getting sore, right between the shoulder blades,,back of the right (troublesome) knee is complaining...thought about at least trying a set of pins...decided a cold Guinness Draught Stout sounded better...

As the Barkeep was wont to call out "(quitting) TIME, Gentlemen, if you please"

Maybe tomorrow, I can try the pins? We'll see...

Stay tuned

Show me a picture, I'll build a project from that

Posts: 9,724

Threads: 0

Joined: Jan 2005

Location: Orlando FL

This looks like a fun project. So do you have to make the sides rounded and then do the dovetails order the dovetails and then plane the sides rounded?

Posts: 4,213

Threads: 0

Joined: Nov 2010

Dovetails are now done...Sellers planes the curve side after that...he also ploughs the grooves for the lid's panel and the bottom panel first..

3 hours of shoptime...on a Monday? 4" of snow outside...guess we be snowed in...

Film at 2300 hrs...

Show me a picture, I'll build a project from that

Posts: 4,213

Threads: 0

Joined: Nov 2010

Laundry started...next...need pins to match the tails. Kind of bass-ackwards for me...but..following the plan as drawn up..

Note the center 2 pins...they are thinner, and angled a bit....use the tails to help lay out the pins..

No.68 saw to saw some lines..

Basically just saw straight down, leaving the lines...it when you start to chop out the waste..

From the outside, just a normal chop out the waste...then stand the board up in the vise, and peel away the insides of the two center pins...THEN try a dry fit..

Repeat for the other 3 corners...dry fits..until all 4 corners are fitted...

Will need some fine tuning...box is square, though. Mallet to assemble....and take apart...

Plans say I need 5/8" thick panels for the lid and the bottom....had to resaw some 7/8" down to ~about 5/8" thick..

Just wasn't the full 6" width....will adapt it to the plan...as for the panel for the bottom?

Will just have to adapt this 1/2" thick panel for the bottom....need to plough some grooves tomorrow...once that is done and fitted, then see about curving the outside of the box....No.4 plane, each side done separately...then another dry fit, before a glue up...about..Friday, maybe?

Stay tuned...

Show me a picture, I'll build a project from that

Posts: 4,213

Threads: 0

Joined: Nov 2010

I just went and watched Episode #2....as the tasks from Episode #1 are done...

So...tasks to be done next, in order according to Paul Sellers..

Size the 2 panels

Groove both panels all the way around

Add a "rebate" to the inside wall of the groove

Groove all four sides to house these panels

Cut a stopped dado in both ends pieces of the box 3/8' wide x 1/8" deep to house a divider...Dado stops just short of a line where the lid will get sawn off.

Mark the radius on the end of each side and a line along the edge to show where to plane to....

Plane to that radius, one box side at a time...saves blow out the ends of the dovetails.

Dry assemble the box, and saw and pare the nubs from where the dovetails stick up proud. Pare to match the radius.

I think THAT will be quite enough, for one day....will see how my back holds up....3 hours seems to be about the time limit, anymore...

Waiting on lunch to settle...then head to the shop. There is a Wind Chill Alert going on outside the door...about 4" of that white crap on the ground,19 mostly cloudy windy degrees....about 50 degrees too cold, for me. 7 more weeks til spring...Hmmmm, any Crockpot recipes for Groundhog?

Show me a picture, I'll build a project from that

Posts: 21,453

Threads: 2

Joined: Mar 2009

Location: IA

I can not wait to see more

As of this time I am now teaching vets again. If you have any lumber scraps we can use them to glue up to make some bowl from a board which we have not done yet.. Thank You Everyone.

It is always the right time, to do the right thing.

Posts: 4,213

Threads: 0

Joined: Nov 2010

Got about half of those tasks done, today...started at 1230 hrs, ended at 1440 hrs....I'm sore, and bushed, and in need of a Guinness Draught Stout...

Grooved the panels for the lid and the box's bottom..long grain by Stanley 45, end grain by..

The Groove Adjuster. Task one done...#2?

all 4 sides get a groove near the top..

And test fitted as I went..

According to the plans, the strip that fits into the groove need to be a bit narrower..

Tablesaw to trim back...enough that the lid could be dry fitted to the assembled box..for now..

When I plane the radius into the sides to make them "curved" the radius stops at that "step"..

Next...Bottom is not 5/8" thick, I had to use 1/2" stock....grooves were adjusted a bit, things got a tad thinner..

Otherwise, just the same as the lid...except this panel was a hair too long, as I found out with the dry fits...Adjusted the ends, grooves and all for the correct length..final dry fit?

Was getting sore, decided to stop here, sweep up the Krunchies,

And call it a day. Always tomorrow, eh?

Stay tuned..

Show me a picture, I'll build a project from that

|