03-19-2023, 02:52 PM

The Kansas City Woodworkers' Guild has a series of "Special Interest Groups" or SIGs. Among them are a CNC SIG, Scrollsaw SIG, Carving SIG and a Hand Tool SIG. Usually they meet once per month for a few hours and investigate some topic associated with the name of the SIG.

The Hand Tool SIG (HTSIG) meets on the 4th Sunday of the month from 2pm to 4pm. Usually we discuss or demonstrate some aspect of handtool woodworking. Could be sharpening one month, cutting joinery another month and tool restoration another. Generally we try to get the topics ready about a month in advance.

So it was interesting to see that suddenly there are a couple of new Gotshall Block how-to videos out on YouTube since we first announced our March Topic. Doubtless a coincidence I'm sure.

Anyway, it also means that I need to go practice a little bit and make sure I can still do what I signed up for or get equipment and material ready for any other demonstrator. Today was practicing the Gotshall Block again. For those who aren't familiar, it is an exercise in stock preparation, layout and joinery cutting. Pretty much every sort of cut required for western joinery appears on the block. It was created by Franklin Gotshall and appears in his book "Making Useful Things of Wood". He calls for the use of poplar in his write-up.

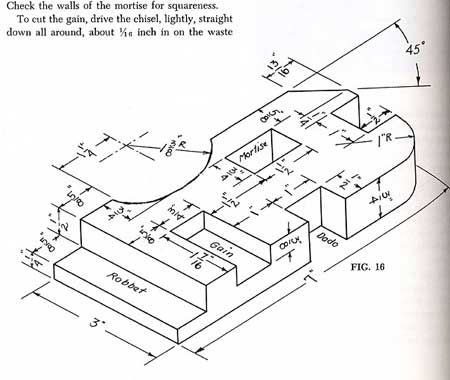

Here's the measured drawing from his write-up:

Here's a quick rendering I did in Fusion360 just for the heck of it:

And after about 2 hours at the bench with a relatively small set of tools, is my practice block:

I forgot to include the 5/8" brace and bit in the photo. I tried to use his instructions for making all the shapes except that I used straight chisels, a rasp and a file for the curved portions instead of a coping saw as suggested. Because I haven't done them that way in a while and felt it would be good practice.

He suggests a grading criteria of no feature off by more than 1/32". I'm going to give myself a grade of "B" because the inside curve is a little to deep and still has some dings in it as well as I dropped the piece on the concrete floor and bashed a corner. Otherwise everything else is within 1/32" of the measured drawing.

The Hand Tool SIG (HTSIG) meets on the 4th Sunday of the month from 2pm to 4pm. Usually we discuss or demonstrate some aspect of handtool woodworking. Could be sharpening one month, cutting joinery another month and tool restoration another. Generally we try to get the topics ready about a month in advance.

So it was interesting to see that suddenly there are a couple of new Gotshall Block how-to videos out on YouTube since we first announced our March Topic. Doubtless a coincidence I'm sure.

Anyway, it also means that I need to go practice a little bit and make sure I can still do what I signed up for or get equipment and material ready for any other demonstrator. Today was practicing the Gotshall Block again. For those who aren't familiar, it is an exercise in stock preparation, layout and joinery cutting. Pretty much every sort of cut required for western joinery appears on the block. It was created by Franklin Gotshall and appears in his book "Making Useful Things of Wood". He calls for the use of poplar in his write-up.

Here's the measured drawing from his write-up:

Here's a quick rendering I did in Fusion360 just for the heck of it:

And after about 2 hours at the bench with a relatively small set of tools, is my practice block:

I forgot to include the 5/8" brace and bit in the photo. I tried to use his instructions for making all the shapes except that I used straight chisels, a rasp and a file for the curved portions instead of a coping saw as suggested. Because I haven't done them that way in a while and felt it would be good practice.

He suggests a grading criteria of no feature off by more than 1/32". I'm going to give myself a grade of "B" because the inside curve is a little to deep and still has some dings in it as well as I dropped the piece on the concrete floor and bashed a corner. Otherwise everything else is within 1/32" of the measured drawing.

Don't sweat the petty things and don't pet the sweaty things. -- G. Carlin