03-23-2024, 09:37 PM

Time to get back to making things....besides making metal shiny? These need a case made..

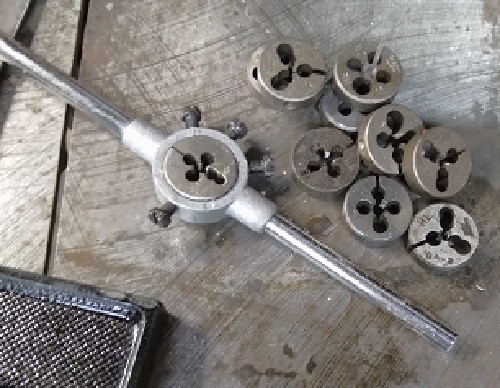

3/4" diameter Dies, and a Die Holder.

Had bought 4 of these planks at Lowes a while back..

The 4th one was cut into 3 equal parts ( other 3 could be made into a case for the "New Chisels"?)

Parts were a bit cupped, so...

This one is to be a lid for the case...the other 2? Well one needed to be worked on a different way...

Traced around the Die holder, bolts and all...may have picked a too big of a blade, was hard to make some of the curves....

Came time to glue these 2 together...Placed them so that the cups met like this..() then used the clamps to flatten them together into the spread out glue..

Until I got a good squeeze out all around...will let this sit a day....then clean things up/out...and level and square it up..

I found an old bit for a Brace drill, that was a bit over-sized from a #12 bit..might be a#13? Intend to drill out a hole for each Die..5 above the holder, and 5 below.

The label each as to what size Die is in the holes.

Add a pair of hinges and a latch....and the Branding iron to the lid.

Stay tuned...

3/4" diameter Dies, and a Die Holder.

Had bought 4 of these planks at Lowes a while back..

The 4th one was cut into 3 equal parts ( other 3 could be made into a case for the "New Chisels"?)

Parts were a bit cupped, so...

This one is to be a lid for the case...the other 2? Well one needed to be worked on a different way...

Traced around the Die holder, bolts and all...may have picked a too big of a blade, was hard to make some of the curves....

Came time to glue these 2 together...Placed them so that the cups met like this..() then used the clamps to flatten them together into the spread out glue..

Until I got a good squeeze out all around...will let this sit a day....then clean things up/out...and level and square it up..

I found an old bit for a Brace drill, that was a bit over-sized from a #12 bit..might be a#13? Intend to drill out a hole for each Die..5 above the holder, and 5 below.

The label each as to what size Die is in the holes.

Add a pair of hinges and a latch....and the Branding iron to the lid.

Stay tuned...

Show me a picture, I'll build a project from that