| Welcome, Guest |

You have to register before you can post on our site.

|

|

|

| Pot stirring time -- tracksaws (or is it track saws?). |

|

Posted by: Rob Young - 03-13-2019, 09:24 PM - Forum: Woodworking Power Tools

- Replies (18)

|

|

I don't work much with sheet goods but in the past I've always used a sorta junky circular saw, but with a decent Freud plywood blade, and a home-made guide to break down the sheets. 1/4" or so over size then over to the table saw which has yet another Freud plywood blade and a ZCI. And often times I'll still add a line of blue tape to the exit side (bottom side for TS). Really does help.

But to the point, I've got on my short list at least two, maybe three projects that are calling (screaming) for sheet goods : bathroom vanity (maybe 2), matching over-the-toilet cabinet and I need to make some additional storage cabinets in my garage. As I've never really like futzing about with the home-made guide I decided to pop for a tracksaw. After much consideration and thought I went with the Grizzly full size model, two lengths of 55" track and once again, an upgraded Freud blade.

And remember, when I say Grizzly here it really means Sheppach because this same saw and rails show up under at least four different names including Sheppach, Aldi/Workzone and Wen.

Sure, I know what many will say, "Go look at the reviews, the Griz always finishes last." Well, I did that and often times (all of the time perhaps) they were using the stock blades. And it was also well documented a few years ago there was a problem with the Griz track having its slick-strips too close together so the saw rocked on the track. Finally, the dust extraction is less than stellar in the not-Festool/not-Metabo brands. The cheaper you go, the messier they get. I got all that. But all of these can be addressed easily.

1) Got the Griz Track Saw + 55" track + clamps for less than $200 (plus about $20 shipping and some tax).

2) Added the 2nd rail so I could run a full 8' if needed.

3) Picked up a Freud LU79R006M20 160mm x 48T thin kerf plywood and melamine blade for just over $20 on Amazon (just checked and the deal has vanished, regular price is about $45 which is still reasonable).

4) I have several rolls of blue tape which works magic.

5) Out of the box, it seems that Griz/Sheppach have fixed the issue with the slick strips being mounted to close together. No side to side rocking of saw. Nice and perpendicular to the track right out of the box.

6) Put tape over the gaping holes in the blade cover and hook up to something with at least 100CFM of air moving ability and things stay pretty clean. No, not Festool/Metabo clean, but acceptable.

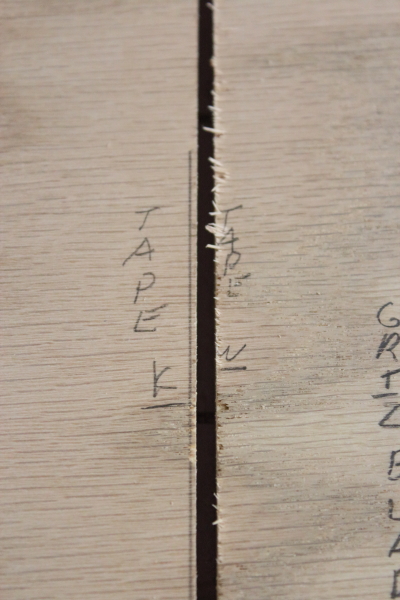

Here's a few test x-cuts using the stock Griz blade (tiny little chunks of carbide and just not that great of a blade).

Obviously a terrible cut in the paper thin veneer (this is the track side or exit side for the blade, the show side would typically be down and I'll show that later but it was supported on some rigid foam insulation). The right side is the "Waste" (marked with a "W"), the left side would have been under the track and is marked "K" for "Keeper". The waste side isn't even suitable for a break-down cut in my option. More on the tearing that is happening on the keeper side later.

Here's what happens with the same blade but adding some blue-tape to the cut-line. When peeling it back off, work at a low angle and with the grain of the veneer so as to not pull out chunks of the veneer!

Better, this is the sort of cut I think of as a break-down cut on the waste side. A bit of splintering but nothing running way in like before. The keeper side is ever so slightly better too.

Now swap out the Griz blade for the Freud blade.

Looks about the same as the Griz blade with the blue tape. Sort of what I expected because that's also what the waste side (and keeper side) look like when I use my home-made guide. Acceptable but not great on the waste side. Biggest bit of tear-out on the veneer is on the "D" of Freud and looks to be maybe 3/16" long.

Finally, Freud blade plus blue tape

Very nice. Certainly well within the quality I could expect on the table saw too.

Now, about the tearout in general and especially on the keeper side no mater which blade was installed. It seems a bit much without the blue tape. Why would that be? Well, it looks like Griz doesn't have quite the right thickness strip installed. Out in front, at the point where a blade cutting maximum depth would be exiting the top side I can slip in two playing cards under the strip. This is the weight of the saw holding down the rail. In the center of the saw, one card and almost two go in. If I put my weight down on things like I was pushing the saw, pretty much just one card.

This tells me that the ZC strip isn't making contact with the work. A little rough measuring with my calipers and I come up with about 0.5mm thinner strip than it needs to be. The strip is about 1.7mm thick but sits in a "rabbet" that is closer to 2mm deep so having a few extra tenths of a mm would be nice to guarantee contact.

Here's the "show face" that would have been held down on the rigid foam. Just two pics instead of 4 since I never added blue tape to this side. It is VERY hard to tell the Griz blade cut from the Freud blade cut but maybe the Freud blade cut is ever so slightly better.

Griz Blade on show face:

Freud Blade on show face:

In closing, what got me thinking about all this stuff was a perfect storm of projects bubbling to the top of my list, prices (Griz deal, Freud deal) and catching a YouTube video out of the corner of my eye one day when I was doing other stuff on the PC. Peter Millard does custom work in and around London from a tiny little shop. Mostly an MRMDF and Domino guy but uses his Festool tracksaw a lot. And he has a few other videos about testing "entry level" track saws and a series where he takes the Sheppach (as sold by Aldi) and sets it up. While he doesn't do the blue-tape trick, he does experiment with different blades and rubber strips with some similar results to mine.

Here's the first video in the series.

I think I'll be just fine with the Griz tracksaw and upgraded blade and just to be safe I'll keep some blue tape on hand. I'm going looking for some thicker rubber to replace the ZC strip on my tracks and I may test again. But honestly, I'm already getting better results than my old method.

Would I get better results with the Festool out of the box. I have no doubt I would. Also would get better results with the Makita or DeWalt out of the box too. Investing and extra $20 for the Freud blade on top of the $200 (plus some tax, shipping and an extra 55" rail so call it $300 all-in) I'm getting better results than before and with maybe another $20 upgrade to the ZC strip I should be doing great. So it comes down to $350-ish money vs Festool at around $700 (plus some shipping, $50?) for the TS55 + one 55" track. And if Festool's TS55 warranty is like those of the sanders, it can be voided if you don't use an approved dust extractor. That is pure speculation on my part as I haven't read the details on the TS55.

The EurekaZone was an option since that could be fitted to my existing circular saw. But since my circular saw doesn't have any dust collection features and it just isn't all that great I dropped that from my list. It also seems the Kreg has entered the tracksaw market in a big way but it is a bit more cash than I want to drop right now and there isn't much of a history with the design yet.

Interesting to note the Griz/Sheppach has a riving knife at its price point. So while I loose a little cutting depth vs my old circular saw, I can gain a riving knife.

So occasional use, particularly for sheet good break-down it is $350 vs $750. I can live with the noise of the Griz motor and my shopvac since I already have good 3M muffs. I can live with the bit of junk spewed out under the blade. I (believe) I can resolve the ZC strip issue and I've always got plenty of blue tape on hand so I can get a perfectly acceptable cut to me.

|

|

|

| Read all posts |

|

Posted by: Turner52 - 03-13-2019, 03:27 PM - Forum: Woodturning

- Replies (1)

|

|

Arlin

Because i am computer challenged the different pictures show up in repeated posts. My problem and not anyone elses. In respose to how I did the one bowl, it it simply a closed segmented bowl which I routed V grooves into and then glued in the darker corian. I complained a few weeks ago about 90 degree router bits that were not 90. The only 2 I have been able to confirm at 90 are whiteside and frued. There is also a note for you about another way you might get some corian, hope that might help you out.

|

|

|

| RIT dyes on wood |

|

Posted by: Jack01 - 03-13-2019, 10:56 AM - Forum: Finishing

- Replies (5)

|

|

RIT dyes on wood -- May be this question is asked before.

Has anyone used RIT fabric dyes on wood?

Here are instructions on their web site Ri dyes

I like to do some experiments using their Golden Yellow or Sunshine Orange dye on Maple, then finish with Zar # 110 Salem Maple oil penetrating stain.

Before I do this, any suggestions? or any experience in this?

|

|

|

| Disappearance |

|

Posted by: Mtobey - 03-13-2019, 10:04 AM - Forum: Woodworking Hand Tools

- Replies (6)

|

|

Hello folks- I have been rendered incapacitated for quite some time. I keep having sequential "TIA's" which add up to lasting physical disabilities/ Several hard falls--ome knocked me out so I got a ride in the meat wagon and did some sheet time. On top of that, my computer went fully belly up and in email section ll was blank. Lost all of my archives too. My Sis bought me an early birthday present- a quite nice laptop. NEW EMAIL---Sprintcar3J@gmail.com I am converting all to Android/Google Chrome. Calls are welcome. ( A new pup has joined the family-- a mostly white Rough Coat Collie. (rare,but AKC approved) She and Buttons have bonded well. She is named "Annie" in honor of my first wife of 33 years. She, Ruth Ann showed up wit excellent puppy food after my grandson' s 7 year birthday party and was quite pleased with her name. Darn, Annie is smart. One half day with us and she is learning stairs, sit,stay and "unquestioned "Come."

I sincerely apologize for frustrations caused by all this. As for tools, I intend to offer some soon. Last time, for the first time ever I had a return. It was justified and I am embarrassed. The returner sent back my payment for return shipping. Such a kind gentleman, a classic Woodnet member. I need to check mouth and iron and capiron upgrades for fit and travel.

A caveat, In the dozens of LN and Hock steel upgrades I have purchased I found far from flat and they take a lot of tedious work to get there. All of my Tormek stuff and stones are locked up and buried deeply, so I cannot prep them myself-- quite a few have never been used.

PS--phone= 563 210 3693

|

|

|

|

Simple three countersink screws to attach the legs...

Simple three countersink screws to attach the legs...